CNC Routing Services

Precision Cutting for Aluminum & Fabrication

Our CNC router gives us the ability to create precise, consistent parts with confidence. Every cut is based on your digital design, which means accuracy isn’t estimated, it is completely controlled. This process removes manual guesswork and ensures parts fit the way you intended them to.

XSF has the capacity to handle large sheet sizes and a variety of materials, we can support everything from one-off to full production runs. The result is clean smooth edging, repeatable accuracy, and parts that are ready to integrate into your project.

XSF does the work in-house, so you know turnaround is faster, communication is easier, and quality stays consistent from start to finish.

Whether you’re prototyping a new idea or refining an established product, XSF’s CNC routing gives you reliability at every stage. With digital toolpaths and controlled repeatability, there’s no drift, no variation, and no compromises from run to run.

Once the toolpath is set, the machines repeats the job exactly as programmed, giving you uniform results across every run.

ACCURANCY

±1/32″ Repeatable Tolerances

Automation ensures consistent fitment and zero guesswork in critical assemblies.

CAPACITY

5’×12’ Sheet Handling

Large-format routing supports single prototypes through full production runs.

SPEED & EFFICIENCY

Fast Lead Times

Quick turnaround with predictable scheduling and repeatable accuracy.

MADE IN THE USA

In-House CNC Manufacturing

All routing, verification, and quality control performed onsite.

Precision Process from Start to Finish

Upload. Approve. Cut. Done.

Our CNC routing workflow is designed to be clear, efficient, and reliable.

We work directly from standard engineering file formats like DWG, DXF, and STEP, so what you design is exactly what gets cut without conversion, redraws, or guesswork. Once we receive a file, the process follows a consistent sequence: review, programming, cutting, and delivery.

Because the workflow is automated and repeatable, the first part and every repeat order match with the same accuracy.

Keeping the entire process in-house gives us full control over quality and turnaround. Whether it’s a single replacement part, a prototype, or a full production run, the process remains predictable, efficient, and built around accuracy.

Versatility in Design

DESIGN FLEXIBILITY

Simple to Complex Profiles

Whether it’s a basic profile or a detailed pattern, the machine follows your engineered design with accuracy.

MINIMUM INTERNAL RADIUS

1/8″ Radius Capability

Tight internal curves are controlled by tooling, allowing detailed shapes without hand finishing.

HOLE DIAMETER CONTROL

Minimum Hole Size: 1/4″ ±1/32″

Small, precise holes maintain consistent fitment, alignment, and repeatability across all parts.

CAD FILE COMPATIBILITY

DWG · DXF · STEP Ready

Standard engineering file formats import directly, eliminating redraws and preserving design intent.

READY TO START YOUR PROJECT?

Whether you already have a prepared engineering file or you’re still finalizing details, getting started is simple.

Call XSF or email sales@xsftruss.com, and our team will review your requirements, confirm material options, and provide turnaround expectations.

XSF offers clear communication, predictable results, and CNC-cut precision every time.

Call or Email Now….

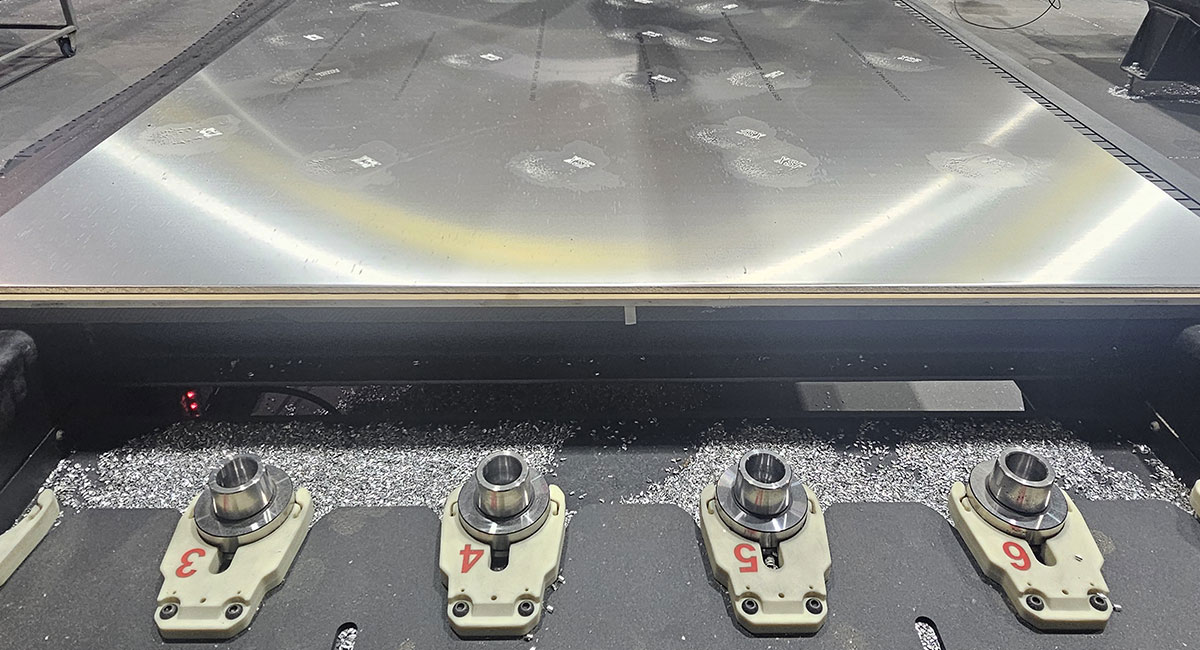

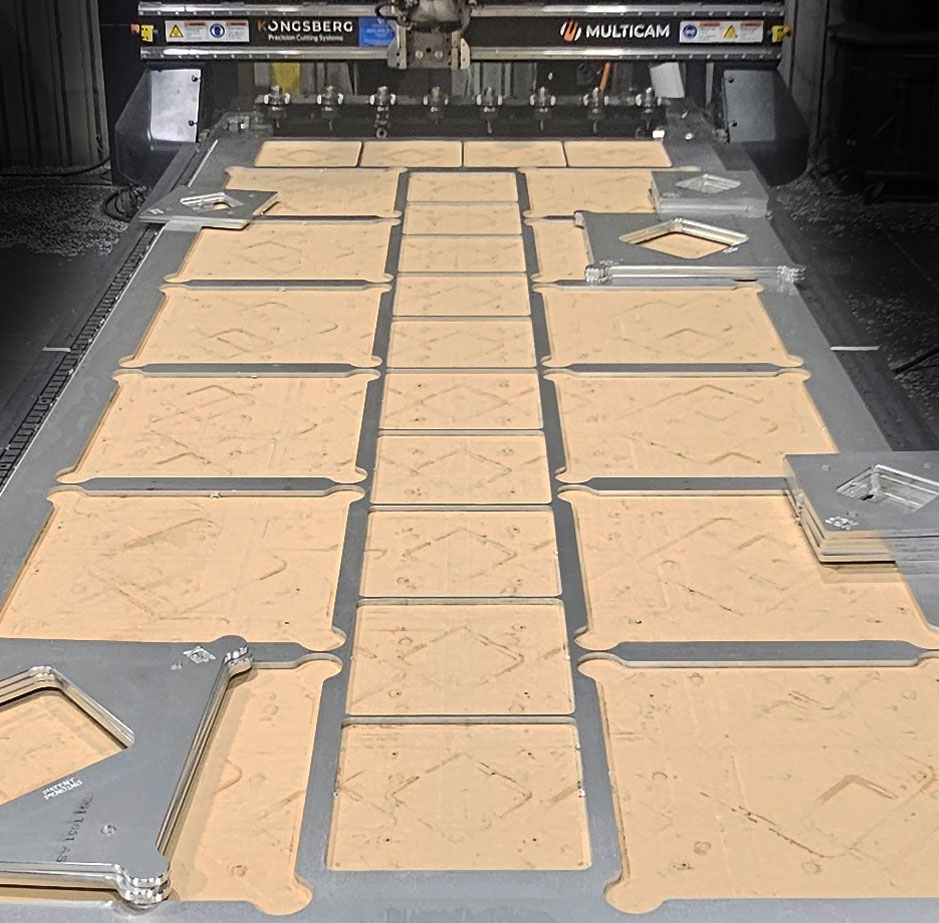

Powered by Proven Equipment

Our CNC capability is powered by two MultiCam Apex3R routers from Kongsberg PCS, a global leader in precision manufacturing. Running dual machines increases capacity and ensures consistent, reliable results, whether it’s a single part or a full production run. Running dual machines gives us increased capacity, consistent output, and reliable delivery for both single-part and production-volume work.

Precision & Consistency

Accuracy matters, especially when a part needs to fit the first time. Our CNC routing process delivers ±1/32″ repeatable tolerances, driven directly from your digital file. Because the workflow is automated through DXF import and CAD-to-toolpath programming, the final part matches the design rather than depending on manual interpretation or handheld tools.

This approach reduces errors, improves repeatability, and ensures that parts remain consistent across single cuts, batches, and repeat orders.

Material Utilization / Waste Reduction

Our routing process is designed to use material efficiently. By nesting parts digitally before cutting, we reduce scrap and make better use of each sheet. With a 5’ × 12’ cutting area, larger parts can be completed in a single pass, lowering waste and improving consistency.

Whether it’s one part or a full production run, the layout remains repeatable, predictable, and highly cost-efficient.