What is Lighting Truss?

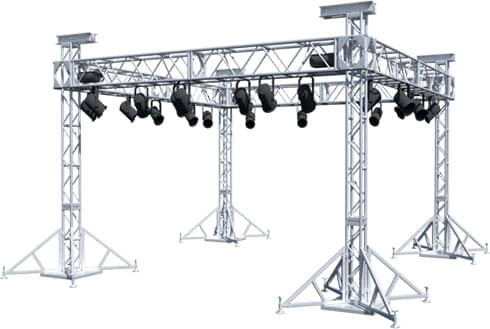

Lighting or stage truss allows lighting designers the freedom to hang LED or Automated fixtures, often called “movers” where ever they choose. Lighting Truss can be found in Theater, concert, performance arts, or tradeshows, arenas and stadiums. Anywhere staging equipment is deployed you are likely to find aluminum lighting truss.

“Sticks” or sections of the truss can be connected together to create a structure allowing lighting fixtures, video, audio or other staging equipment to be hung with ease. Lighting Truss comes in several different lengths and when connected together, create longer spans or different shapes.

This article contains information and video discussing the many areas lighting truss:

- Types of Lighting Truss

- What is Truss Made of?

- What are the Components?

- Common Sizes

- How Truss is Deployed

- Lighting Truss Applications

- How is Lighting Truss Manufactured?

- Truss Safety and Load Tables

- Common Truss Accessories

This video answers the question….What is Lighting Truss?

What is Lighting Truss Made of?

The primary materials most commonly used for stage lighting trusses are Aluminum and Steel.

Aluminum, because of its durability, light weight and ease of transport, is the optimum choice for use in concert or stage production. Its weight allows for a quick and easy setup and teardown.

For installations that are permanent such or where high load ratings are required steel truss is the easy choice. No matter what the project, always know the load ratings of your truss and deal with professionals.

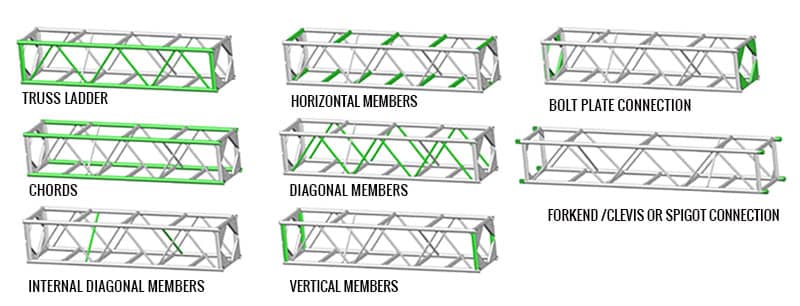

Components that make up Lighting Truss.

- The Chords

- The Truss Ladder

- Horizontal Members

- Chords

- Diagonal Members

- Internal Diagonal Members

- Vertical Members

- Bolt Plate Connection

- Forkend, Clevis or Spigot Connection

Common Sizes

Lighting truss comes in sectional lengths that may be connected together to create longer spans or different shapes. These truss structures are used to support lighting, audio and video equipment. The most common truss lengths are 1 foot, 5, 8 and 10 feet.

For a complete line of lighting truss sizes and variety look at our Truss Page.

Deployment Terms

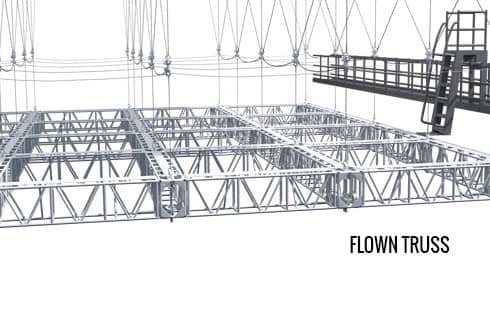

When Lighting truss is supported overhead it is referred to as being “flown”. If the truss structure is standing on the ground or is part of a larger design that is free standing it is most often called “ground supported” or ground support.

Click here for more information on Ground Support Systems

For an example of flown truss see the Tacoma Dome installation.

Formats

The most commonly used format for lighting truss are Box truss and Triangle truss. A valuable format that XSF has designed is Space Saving truss. Space Saver Truss can transport 100’s of feet more of truss in truck trailers because of its unique design.

Lighting Truss Applications

The most commonly thought of applications for lighting truss are concert, stage, theatrical, architectural, trade show and houses of worship. If you are to dig a little deeper you see that lighting truss is found anywhere lighting fixtures are deployed.

| Concerts | Exhibits |

| Stadiums | Theaters |

| Arenas | Touring Productions |

| Houses of Worship | Theme Parks |

| DJ Booths | Department Stores |

| Race Finish Lines | Bars |

| Tradeshows | Towers |

| Restuarants | TV Studios |

| Movie Sets | and many more.. |

The Video above contains video samples of Arena, Dome and Stadium Truss Applications

Manufacturing and Fabrication

Lighting or stage truss is typically fabricated from 2 inch round aluminum tubes referred to as chords. Truss sections generally consist of 2, 3 or 4 chords. Two chord light truss is often referred to as Ladder Truss, three chord truss are often referred to as Triangle Truss and four chords would be a box truss.

The diagonal members or webbing in the truss is generally a smaller diameter round tube. There are a variety of connections available on the market that provide an array of different strengths and load ratings.

This video shows photos of the inside of an Aluminum Truss Fabrication and Manufacturing facility

Truss Safety

All lighting truss to be used overhead should be engineered with published load ratings and allowable load tables.

Below is an example of a load table for the XSF 12″ x 12″ Plated Utility Truss

| Span (ft) | UDL (plf) | CPL (lbs) | 3PL (lbs) | 4PL (lbs) | 5PL (lbs) |

|---|---|---|---|---|---|

| 10 | 553 | 2766 | 2075 | 1383 | 988 |

| 20 | 134 | 1342 | 1007 | 671 | 479 |

| 30 | 56 | 850 | 637 | 425 | 303 |

| 40 | 29 | 582 | 434 | 291 | 211 |

The above Video is a Video Guide to Reading Truss Load Ratings & Allowable Load Tables.

Common Truss Accessories

Wedges

Corner blocks

Pinch Blocks

Kabuki’s

Truss Toppers

Half Couplers

Outriggers

Sleeve Block Adaptors