Repairing Damaged Aluminum Truss

The repairing of damaged aluminum truss is about customer support and getting your truss back in service as quickly as possible.

At XSF, support is a key part of our business and as one of the leading truss manufacturers in the United States product support is another reason our customers keep coming back. Inspecting truss inventory after use is a very important step in maintaining truss care and safety on future concerts, tours, shows or whatever your next job site.

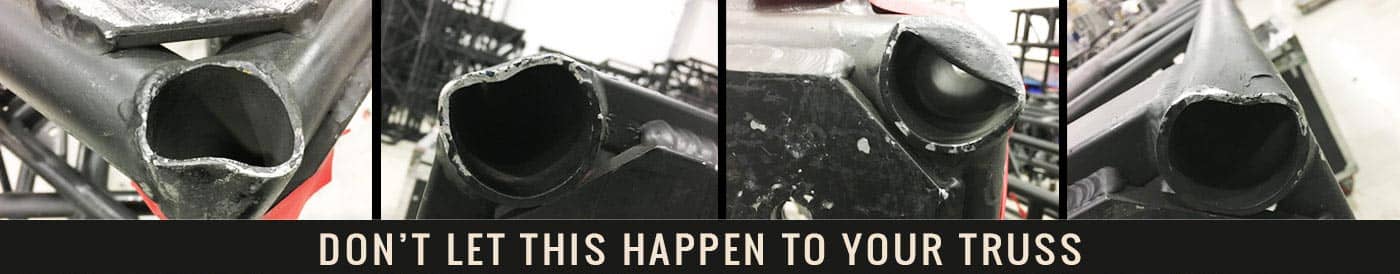

In many cases, truss that is found to have damage during the inspection process can be repaired. Truss repairs should be performed by the manufacturer to ensure that the truss is in certified good working condition.

The care, managing and inspection of truss supply and inventory are both:

- largecost savings to our customers

- important safety measures that should not be overlooked.

Take a look at our Truss Inspection Video and for More details, visit our Truss Inspection Page

To help ensure safety and efficiencies we’ve always provided Free Truss Inspection at our facility in Sulphur Springs along with repair recommendations. Working together we can help keep your truss safe and in service.

Truss Repair is a huge cost savings benefit, far below the purchasing of new replacement truss.

XSF’s 100% USA Made Truss is designed and engineered to last a lifetime with proper use, handling and inspection.

4 Simple Steps to Aluminum Truss Inspection, Repair and Recommendation:

- Contact XSF at 903-438-1100

- Send any amount of truss to XSF. ( A single truss, a Pallet full,or a Truck Load)

- XSF will inspect each aluminum truss section at No Cost to you.

- We will provide a repair recommendation for each truss piece you send.

*In some cases truss will be deemed non-repairable, and in other cases the damage may be within the guidelines set for in E1.2 and can be returned to service as is. The Entertainment Services and Technology Association’s Technical Standard Program developed the ANSI Entertainment Technology Standard E1.2 which contains minimum required inspection routines and guidelines for truss inspection. The XSF Truss Inspection Video outlines the E1.2 standard which is also available for download for free at www.ESTA.org.

Properly inspecting your truss will ensure that it’s in safe working condition each time the truss is used.

We have in-house professionals that understand the science of aluminum truss. Repair is an inexpensive option that is often overlooked. While we are active advocates for recycling aluminum materials when a truss is damage beyond repair, a simple repair can prolong the life of a truss significantly use.

XSF adheres to the Entertainment Services and Technology Association’s Technical Standard Program developed the ANSI Entertainment Technology Standard E1.2 which contains minimum required inspection routines and guidelines for truss inspection.

If you perform a visual inspection and feel the truss may have been compromised in any way we encourage you to contact us to discuss the damage and possibility for repair.

To avoid Truss Repair this video on Truss Use and Handling is an excellent Resource Guide. For additional information you can also visit our Truss Use & Handling webpage.

TRUSS REPAIR and INSPECTION FAQ

Are there different types of inspections and when should I inspect my truss?

ANSI E1.2 defines 3 types of truss inspections:

- Initial Inspection

- Frequent Inspection

- Periodic Inspection

Initial inspection is required when truss is acquired, when you purchase new from the manufacturer or used. Dated records should be kept on file by the owner and maintained for the duration of the possession of the truss.

Frequent inspections are defined as visual inspections to be conducted prior to each use and immediately after any incident that may have in anyway caused damage to the system or truss. Records are not required to be kept for frequent inspections.

Initial and frequent inspections are a visual inspection performed by a competent person with the following items inspected:

- Geometry of Truss or twisting, racking or bending

- Truss Members for dents, bends, Abrasions or missing members

- Truss Connections for flatness or deformation

- Fastening Hardware for proper Grade, Deformation or Excessive wear

- Welds for breaks, cracks or deformation

To recap each truss shall be inspected for these items upon initial purchase and prior to each use.

Periodic Inspections are defined as annual visual inspections with dated records to be kept on file with the owner. Periodic inspections shall be performed by a competent person with the following items inspected:

- Geometry of truss for twisting, racking, bending, sweep or camber

- Trust Members for Dents, bends, abrasions or missing members

- Connection Plates for flatness, deformation, excessive wear or corrosion

- Pinned Connecters for Abrasion, deformation and method of connection to the truss

- Fastening Hardware for proper grade, deformation or excessive wear

- Welds for cracks and abrasion

Any weld thought to possibly be defective shall have additional non-destructive testing performed by a qualified person. Non-destructive testing may include dye penetrant testing.

To recap each truss shall be periodically inspected a minimum once a year.

What Constitutes excessive damage to a truss?

During the inspection process it is important to know what is considered damage that would warrant removing the truss from service.

Refer to manufacturer guidelines for abrasion or loss of material from dings, scrapes, gouges, scratches or C-clamps. Xtreme Structures recommends that material loss shall not exceed 25% of the wall thickness of the damaged member of the truss. A truss with any sign of dents, holes, cuts, bent members or plates, cracked or broken welds, corrosion, or excessive wear around connections shall be considered damaged. Xtreme Structures recommends a tolerance of 1/8” out of square for truss exhibiting twist, racking bending, sweep or camber.

What do I do with damaged truss?

Damaged truss should be noted in the inspection documents, clearly marked, and removed from service immediately. A qualified person shall perform and document an assessment of the truss to determine if it can be repaired and returned to service. Any truss deemed to have irreparable damage shall be permanently removed from service. Repairs to damaged truss shall be made according to the manufacturer’s recommendations by a qualified person. Repairs involving welds shall be performed by an AWS certified welder.

The inspection criteria in this article is provided for a variety of uses that are generally confined to the entertainment industry and apply to a range of structural products subjected to normal atmospheric conditions.

Properly inspecting truss is key to maintaining a safe working environment around structural components.