What is a Truss Tower?

A Tower truss is a truss structure generally used as a column to support overhead truss and rigging in both indoor and outdoor situations.

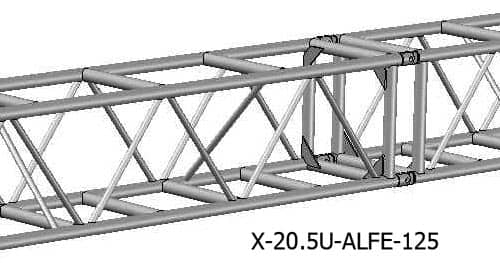

Truss Towers differs from a standard truss in that it contains diagonals in 3 or all 4 sides of the truss. These additional diagonal lacing strengthens the truss and provides additional resistance against lateral loads such as wind or seismic (earthquake) loads.

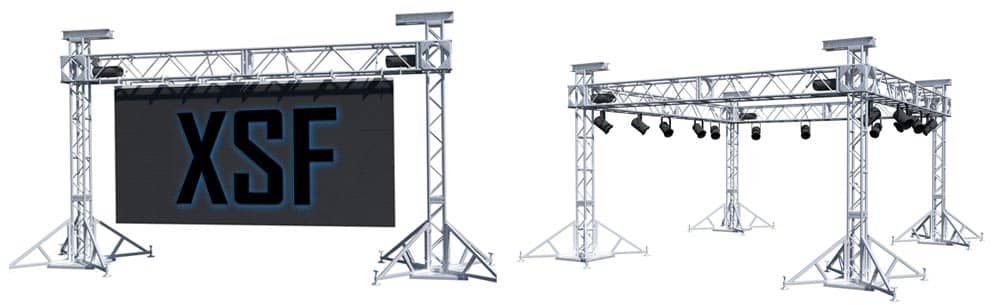

To find out about XSF custom Truss Towers or the many truss towers XSF carries click here

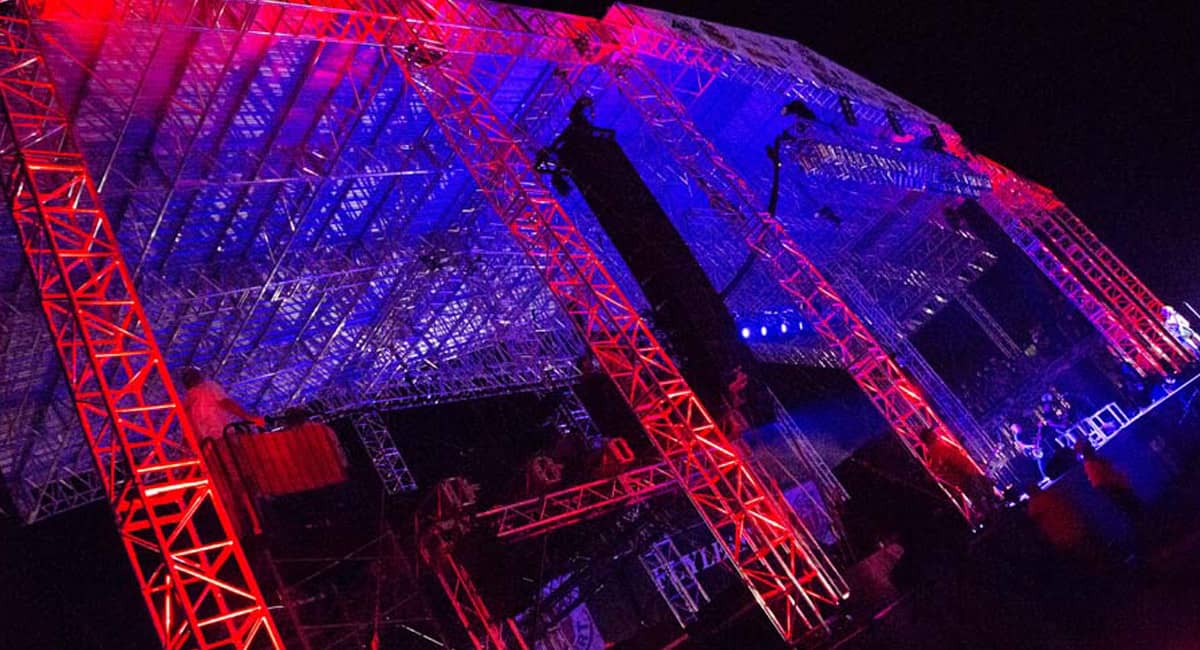

Tower truss can be used as a free-standing tower for lighting or audio applications or can be part of a multi-tower roof system. A basic 4-Post system would be a small roof or canopy structure that has 4 towers or “posts”.

Larger outdoor roof systems can have numerous towers incorporated into the design.’

Common uses for tower truss outside of the entertainment industry includes radio or transmission towers, electric line towers, platform supports, or observation decks that can stand up to 2,000 feet tall.

The Eiffel Tower is perhaps the most famous example of a lattice tower and was the tallest lattice tower in the world for a record 68 years, from 1889 to 1957.

See More XSF Truss Tower Images Below or Visit Our Gallery Page

This page lists the structural components of a Truss Tower. One key mechanical workings of a Truss Tower can be chain hoists. For information on chainhoist and the many options that can be used on a Truss Tower visit our Electrical Chain Hoists Page

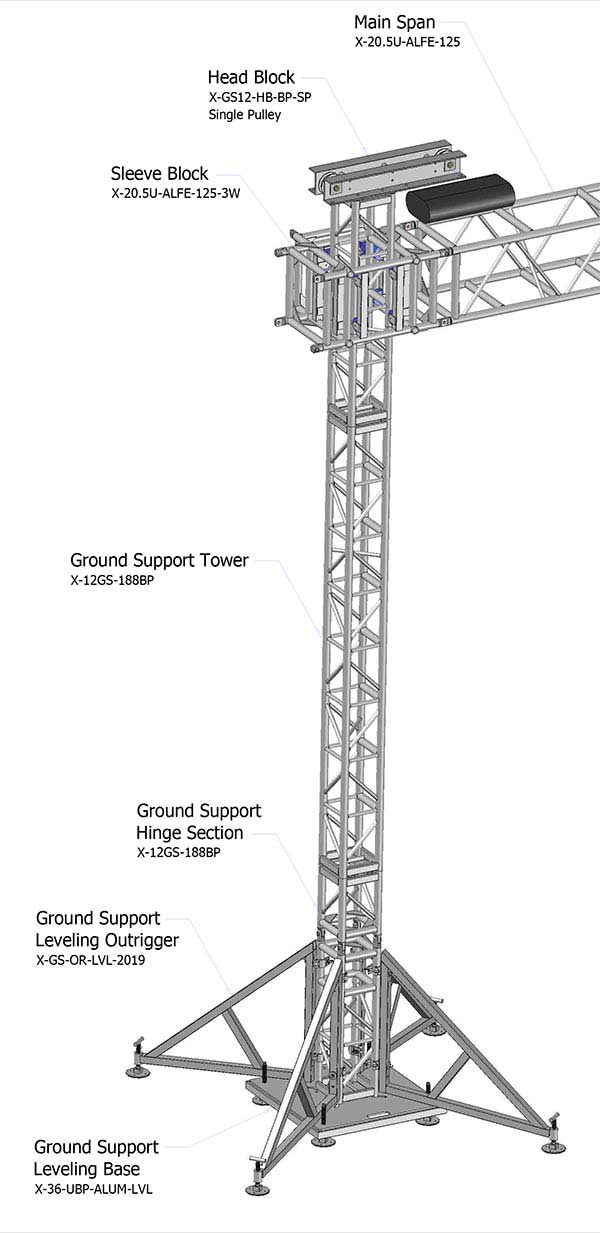

BELOW ARE THE PRIMARY STRUCTURAL COMPONENTS THAT MAKE UP A TRUSS TOWER

Main Span Truss Sections

The main span, as the name says is the primary span of truss running horizontal between the vertical towers. The allowable loads and length of the main horizontal span of truss factor into the design of the truss towers.

This horizontal truss span allows for the attachment of moving lights, video production, automation and many other devices.

It is very important to have a qualified person or a professional engineer design and approve Truss Tower loads prior to use.

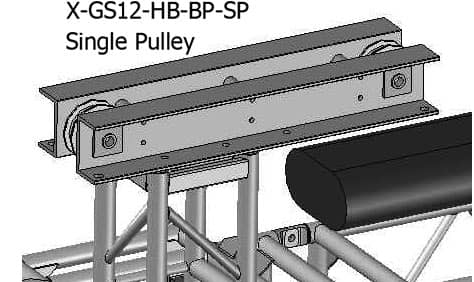

Head Block

The Head block generally sits atop the tower truss and includes rotating sheaves that allow the chain from the chain hoist to be securely placed over the top of the tower.

Using a chain hoist and headblock allows personnel the safety and convenience of rigging the main truss span completely at ground level and then raising the truss to the desired height or elevation.

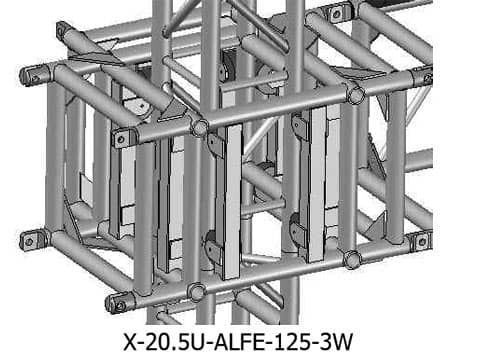

Sleeve Block

The Sleeve Block attaches to the main truss span and contains internal wheels that provide a sleeve for the tower truss. Sleeve blocks are manufactured in different sizes and variations to accommodate different sizes of tower truss and main span truss.

The sleeve block is an engineered component that generally meets or exceeds the strength of both the tower truss and the main span of truss.

As the chain hoists raise the main span of truss into place, the sleeve block keeps the truss in line and acts as a guide that prevents the main truss span from swaying or damaging the tower truss. All together the chain hoists, headblocks and sleeve blocks are a critical combination of components in ground support roof systems or goal posts.

Ground Support Tower

The science, safety, and proper engineering of ground support systems are so important and cannot be stressed enough. The width of the main span, the height of the towers and other variables such as outdoor wind loading or seismic loading are all taken into account in the design of Ground Support Truss Towers. The required loads to be hung from the ground support system play a major role in the design of tower trusses in a ground support system.

There are many variables that make up a well-engineered and well-built Truss Tower system. The Ground Supports Towers could be termed the heart of the entire system.

Truss towers provide stability and rigidity while the system is in operation with a safe and effective means to disassemble the system quickly.

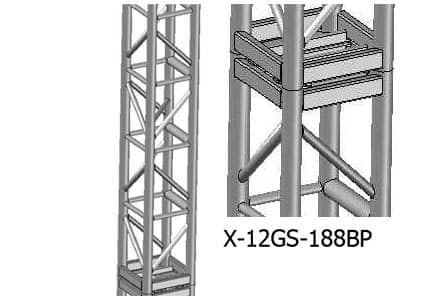

Hinge Section Ground Support

The Tower Truss Hinge Section is a short hinging tower that is designed to allow for easy and safe erection of towers. The complete tower may be assembled at the ground level and hinged up into place using a tower lifter.

For more information regarding hinging sections and tower lifters check out one of our tower lifter video.

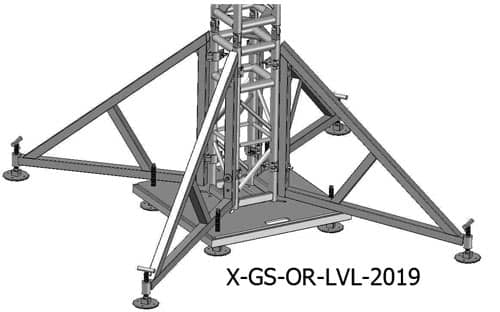

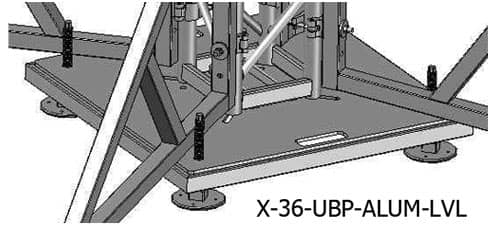

Ground Support Leveling Outrigger

Outriggers provide additional stability at the base of a tower truss to help resist lateral loads such as wind or seismic activity. They also provide a measure of safety during erection to help the towers stand freely prior to completing erection.

The leveling feature of the outrigger allows the end-user to adjust the leveling pads for a firm contact on the ground or support surface.

The leveling outriggers can conveniently rotate and adjust from side to side for ease of installation

Ground Support Leveling Base and Base Plates

In most applications the bottom of the Truss Tower will have a base plate providing the tower with a firm platform on which to stand. The leveling Base Plate mounts to the bottom of the truss tower and bolts into the foundation or support surface.

The leveling feature allows the base plate to be adjusted so that it is firmly positioned on the foundation and also allows the user to level the truss tower once it is up and in place. Base Plates come in different sizes, and can be manufactured from aluminum or steel.

Please refer to this link for more information regarding XSF Base Plates.

More Information on Truss Towers

Because of the many factors involved in the engineering calculations for a tower truss, standard load tables are not provided by XSF for tower truss. The design includes more factors than standard truss used in a horizontal application.

XSF offers engineering for each tower truss application to ensure the correct towers are provided with safety in mind for your project.

For Custom & Available Truss Towers visit our truss tower product page.