Introduction to XSF | Manufacturing and Custom Truss Fabrication

Xtreme Structures and Fabrication is a premier provider of standard and custom aluminum truss used in many applications such as concert and stage lighting. We manufacture and build custom stages, roof systems, hardware, rigging, risers, platforms, and exhibit components.

Founded in 2002 XSF has a large, modern fabrication facility in Sulphur Springs, TX. We have a skilled team that delivers the highest quality service and products to our customers.

XSF INNOVATIONS – DESIGNING THE FUTURE OF TRUSS

Making your business, production, and events, safer, cost-effective, and easier to execute.

The core value and commitment of our product development is to simply build the best and most effective tool for the job. XSF builds products that will streamline user productivity and workflow, allowing peace of mind that our products always deliver.

ConneX – The Indexable Forkend Truss

This Indexable Forkend Truss is quick and easy allowing the user to seamlessly adapt and change the configuration of the fork ends without skipping a beat. This simple “maneuver” is completed without the use of any tools by simply rotating the fork end 90 degrees by hand. In seconds, the fork ends can change from a horizontal positioning to a vertical configuration.

ConneX also has the added bonus of cost savings.

More Information

https://www.xsftruss.com/indexable-forkends-truss-system-connex/

MAV Truss- Moving Lights | Automation | Video Production

What is the strongest Moving Light Truss on the Market today? The XSF MAV Truss. Take a look at the engineer-certified Load Tables below and see for yourself. Along with the many other features listed below the XSF MAV (Moving Lights, Automation, and Video Production) Truss is highly “customer-friendly”.

If you’re looking for long span, easy to use, cost-saving benefits look at MAV. We encourage you to explore your options then call us for more information on this innovative product from XSF Truss.

More Information

https://www.xsftruss.com/lighting-automation-video-mavtruss/

Integrated Rig Point – Rigging Production-

The XSF (patent pending) Integrated Rig Point (IRP) provides a whole new way to rig your truss safely. The IRP is a heavy-duty aluminum rig bar that provides an engineered rig point with a 1-ton load rating at each panel point within the truss. Welding the rig points into the truss at precise panel points ensures the 1-ton load rating is at the safest location possible.

At a fraction of the cost of removable rig points, the IRP can be installed at every panel point, or can be selectively placed a la carte at fewer panel points.

More Information

https://www.xsftruss.com/rigging-truss-integrated-rig-point-product/

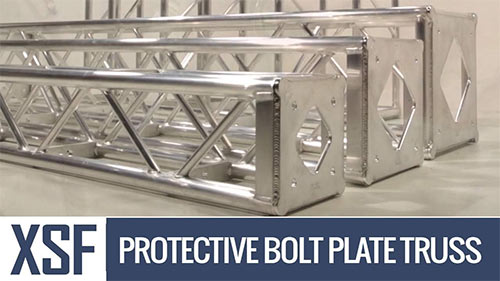

The Protective Bolt Plate Truss

Protective Bolt Plate Truss provides a new engineered end plate design (patent pending) which includes circular ears at each corner that prevent damage to the chords from dropping or dragging. Aluminum Truss is often dropped on hard floors or unnecessarily damaged from dragging, costing users thousands of dollars.

We looked to eliminate this problem and extend the life of the truss. Protective Bolt Plate truss come in standard sizes including 12”x12”, 12”x18”, 16”x16”, and 20.5”x20.5”.

More Information

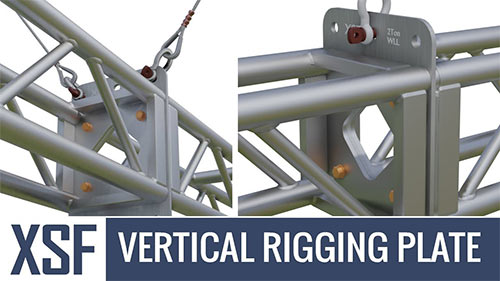

Vertical Rigging Plate

Rigging from true centers or exact point, lengths of span is one of the primary benefits of this product but there are many more. When assembling truss spans together these lightweight and easy to use plates can be conveniently bolted between each stick of truss. With rig plates you use none of the available space on the truss, this allows more room for lighting, video devices,

LED screens or whatever is needed for your project. As the imagery below illustrates, the Vertical Rig Plates are an easy, “clean” and simple solution, but the benefit that our customers most prefer is the cost.

More Information

A TRUSSUMENTARY – MISSISSIPPI COAST COLISEUM

1 Plan, 6 companies, 2 arena grids and the evolution of a magnificent coliseum in Mississippi.

An exciting project that changes everything for the Mississippi Coast Coliseum is documented on video by Digital Base. This collection of videos features, the full “Trussumentary”, a time-lapse video, and the feature Trailor video.

Rigging Arena Grid Installation Mississippi | A Trussumentary (full version)

A large scale, arena grid installation at the Mississippi Coast Coliseum is documented in this 30-minute “Trussumentary” by XSF Truss. This Trussumentary introduces us to the companies involved in the project and the many challenges they faced in designing. engineering, test fitting, and installing this arena truss grid system that would change everything for the better at the Mississippi Coast Coliseum.

A film by Digital Base

More Information

https://www.xsftruss.com/arena-installations/

https://www.xsftruss.com/aluminum-catwalks/

https://www.xsftruss.com/arena-dome-rigging-grid-system-mississippi-coast-coliseum/

A TRUSSUMENTARY – Mississippi Coast Coliseum | The Time Lapse

In early 2020, Digital Base Productions followed the XSF crew through a large Arena Grid Installation at The Mississippi Coast Coliseum. XSF fabricated 2 arena grids with catwalk access and partnered with Conder Inc. for the installation which was completed in 2 weeks. The primary project specifications are listed below: Grid Sizes: Main Grid: 107′ X 58′ Secondary Grid: 70’ x 31’ Primary Products Used: Custom 20.5” x 32” Catwalk Truss Custom 24” x 20.5” Arena Grid Truss with walk surface Weight Capacity: Main Grid: 120,000 pounds Secondary Grid: 101,000 pounds Designated rig points designed into the truss system are capable of supporting a single point load of 8,000 pounds.

More Information

A TRUSSUMENTARY – Mississippi Coast Coliseum | The Trailer

A TRUSSUMENTARY – The Trailer In early 2020 XSF Truss, Conder Inc., Simpkins & Costelli and a camera crew descended upon the Mississippi Coast Coliseum in Biloxi, Mississippi to do a major Arena installation.

This trailer gives us a sneak preview into the 2 Grid installation which concluded March of 2020. Complete with interviews and timelapse video, the crew takes us on an insightful tour; the construction and installation of the black powder-coated coliseum truss grid and catwalks.

More Information

https://www.xsftruss.com/arena-dome-rigging-grid-system-mississippi-coast-coliseum/

IN THE SHOP –EXPERT INDUSTRY SERVICES

Operated and managed by industry experts, the XSF shop is always a

“buzz of activity”.

As you browse the XSF galleries you begin to understand how XSF has become such a champion leader in the truss industry. Check out the videos below to see our Texas-sized Test-Fit facility as well as some of the expertise XSF possesses.

XSF Test Fits Every Truss Order We Fabricate

Test Fit and Quality Control are key components of a successful project. Large Arenas, Ground Support Truss Systems, Stadium, Concert or Theater Stage Builds have many pieces and accessories that you do not want to leave to chance. Our Pre-Assembling, Quality Control, and verified test fit process ensure that every order is perfect before it leaves the XSF Truss facility. We have a massive Truss Manufacturing and Fabrication facility that provides more than enough room to Test-Fit the largest truss projects.

More Information

Aluminum Truss Inspection

XSF truss is designed and engineered to last a lifetime with proper use, handling and inspection. Properly inspecting your truss will ensure that it is in safe working condition each time the truss is used.

The Entertainment Services and Technology Association’s Technical Standard Program developed the ANSI Entertainment Technology Standard E1.2 which contains minimum required inspection routines and guidelines for truss inspection. This standard is available for download from the ESTA website at www.ESTA.org.

More Information

Aluminum Truss Use and Handling

The proper use and handling of aluminum truss can significantly increase the lifespan of any truss. Always avoid unnecessary abrasive or impact damage to the truss such as dragging or dropping the truss if at all possible. Always use enough people to ensure that the truss is properly handled when moving truss by hand.

Dollies should also be used when moving truss to prevent dropping or dragging the truss members. Always use caution when moving trusses with a fork lift and ensure that the person operating the machinery is properly trained and certified in the use of a fork lift.

The steel forks of the lift can easily damage the aluminum members in a truss if not used properly. If at all possible place the forks under the truss to avoid damaging the diagonals and internal members.

More Information

https://www.xsftruss.com/truss-use-handling/

https://www.xsftruss.com/technical-design/

About XSF Truss

XSF is a premier provider of standardized truss sizes, as well as custom stages, roof systems, hardware, rigging, risers, platforms, exhibit components and aluminum, stainless and carbon steel structures for use in the Entertainment, Worship, Theatrical, Manufacturing and Trade Show industries.

Founded in 2002 and based in Sulphur Springs, TX, we are proud to also offer products through our many distributors throughout the USA. Our products are safe, reliable, user friendly and always the highest quality available.

With innovative vision and superior customer service, XSF is ready to meet your trussing and staging needs.

More Information

2000 Pound Certified Truss Rating

XSF has a certified load rating of 2,000 pounds on any horizontal member in our standard lineup of trusses. That is 8 times more than any other truss! “2000lb Rating”XSF has completely changed the Truss Industry once again… because when it comes to ‘what’s hanging over your head’… STRENGTH MATTERS! XSF has recently put their “Made in the USA” truss to the test and the engineering results are in. Once again, XSF has not only passed the base qualifications for truss strength, but has completely blown the standard out of the water!

For years, numerous truss manufacturers have published their standard allowable Dead Load for on horizontal members in a truss at 250 to 350 pounds. XSF, along with Clark Reeder Engineering, has a certified safe allowable load rating of 2,000 pounds per horizontal! That is as much as 8 times stronger and more reliable than ANY OTHER TRUSS MANUFACTURER can give you.

More Information

https://www.xsftruss.com/2000-pound-truss-weight-rating-capacity/

What is Lighting Truss?

Lighting or stage truss allows lighting designers the freedom to hang LED or Automated fixtures where ever they choose. “Sticks” or sections of the truss can be connected together to create a structure allowing lighting fixtures, video, audio or other staging equipment to be hung with ease.

Lighting Truss comes in several different lengths and when connected together, create longer spans or different shapes. In this video you learn: What is Lighting Truss Made of? Components that make up Lighting Truss. Common Sizes, Lighting Truss Applications AND MUCH MORE!

More Information

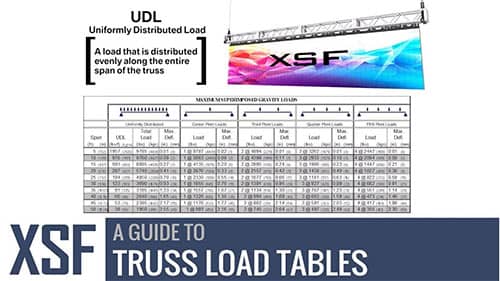

Load Tables and Allowable Load Ratings for Truss

Guide to Reading Truss Load Ratings & Allowable Load Tables. At XSF we are committed to safety. Our load tables are all produced by third party Engineering Firms with many years of experience in the truss industry. The allowable load ratings shown in these tables are all verified with testing that allows XSF customers the confidence of safety. This Load Table Guide YouTube video will help you determine the appropriate truss to use for your truss application, or conditions based on load ratings.

Learning how to correctly read allowable load tables is an important skill when working with truss and rigging no matter what the application is. If you require any assistance or if your load case scenario falls outside of the maximum allowable loads in our tables, we strongly recommend you always consult an industry professional or engineer before loading components on to any truss.

More Information

https://www.xsftruss.com/load-table-and-ratings-guide/

https://www.xsftruss.com/infographic-how-to-read-truss-load-tables/

BEYOND TRUSS – DESIGNING PRODUCTS FOR CUSTOMER NEEDS

Manufacturing and fabricating USA Made Aluminum Truss since 2002.

Concert Production, Houses of Worship, Arenas, stadiums to Exhibits, Events and Tradeshows, where ever you find truss you can find XSF products. We are building the future of Truss.

Truss Corner Block Adapter Kit

A Sleeve Block Adapter Kit is a highly useful mechanism that can be used for many stage truss and lighting applications. If your job has a Ground Support System, Four Post System, Goal Post or 2 Post System, the XSF Sleeve Block Adaptor Kit may be an excellent solution to consider.

Xtreme Structures sleeve block adapter kit consists of eight caster wheel brackets. Each sleeve block adapter is bolted into a standard 20.5 inch 4-way corner block without compromising the engineered load rating. Long bolts are included in the kit and are used to bolt the truss and adapters to the corner block at the same time.

Once bolted in place, the adapter kit provides wheel guides for use with 12 inch by 12 inch standard format tower truss.

More Information

Space Saver Truss

The XSF Space Saving Truss is a unique truss design that allows the truss to nest on itself and stack up to 10 high on a truss dolly. Stacking the truss 10 high allows for 150 trusses to be loaded onto a single tractor trailer, greatly reducing the number of trucks required to transport the truss. In comparison, shipping other trusses of the same size and strength will only allow for a total of approximately 60 trusses per truck.

More Information:

Light Duty Line Array

This video shows the process of raising and securing our XSF light duty line array tower. The line array is made using a 12×12 bolt plate truss and a few custom components.

The tower consists of 25 feet of truss and has a capacity of 2,600 pounds with tower truss and 2,000 pounds with standard utility truss for indoor use. For outdoor use the tower is engineered for wind speeds up to 45mph and can support 1,500 pounds. Overall height is 27 feet. Contact XSF at 903-438-1100 for more information.

More Information

Light Duty Line Array Components

This video shows the truss components of our XSF light duty line array tower.

The line array is made using 12×12 bolt plate truss and a few custom components.

The tower consists of 25 feet of truss and has a capacity of 2,600 pounds with tower truss and 2,000 pounds with standard utility truss for indoor use. For outdoor use the tower is engineered for wind speeds up to 45mph and can support 1,500 pounds. Overall height is 27 feet.

More Information

https://www.xsftruss.com/truss-array-towers/

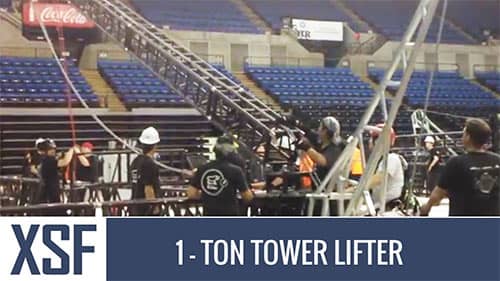

XSF 1-Ton Tower Lifter

XSF’s 1-Ton Tower Lifter raising a XSF 16×16 Fork End 40′ tower. The tower lifter uses a 1-ton CM chain hoist and pins to the existing connections on the 4-way sleeve block.

The spine truss is an engineered design that works both with our XSF box truss as well as the XSF space saving truss. The tower lifter is quickly removable allowing 1 lifter to raise all towers.

More Information

XSF 2-Ton Tower Lifter

XSF’s 2-Ton Tower Lifter raising a 16×16 heavy duty 45′ tower. The tower lifter uses a 2-ton CM chain hoist that remains on the tower to lift the truss grid into place.

The tower lifter is removable allowing 1 lifter to raise all of the towers.

More Information

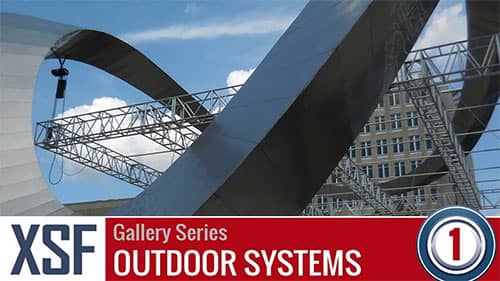

TRUSS GALLERY SERIES – 6 EPISODES

Gallery series, featuring some of the things we’ve built and places we have been.

This 6 episode series was part of a promotional piece we built for Lighting Dimensions International in 2019. It illustrates a wide range of wonderful projects we have had the privilege to be a part of.

Outdoor and Ground Support Truss Systems

Episode 1

Episode #1 in the XSF Truss Gallery Series looks at some of the Ground Support and Truss Systems XSF have had the privilege of being involved in.

More Information on Outdoor Systems

https://www.xsftruss.com/truss-ground-support-systems/

https://www.xsftruss.com/truss-roof-system/

https://www.xsftruss.com/truss-ground-support-systems

Arenas, Domes & Stadium Truss Applications

Episode 2

This video illustrates the importance of having a team that is experienced, and knowledgeable in large scale truss structure applications. From engineering, fabricating, erecting and design XSF understands and can execute these large projects start to completion. Rigging Grids, Catwalks, roof trusses and integrated fall protection. Some of the features of this video are the Huntsman Arena, The Tacoma Dome, UNLV – University of Nevada Las Vegas and the Atlantic City Boardwalk Hall.

More Information

The XSF Shop -Aluminum Truss

Episode 3

As one of the largest manufacturers of aluminum truss, XSFtruss also offers many other products and services that you may not be aware of. Engineering | Technical Design | Powder Coating | Truss Inspection | Test Fit | Truss Use and Handling | Fall Protection | Chain Hoists and Rigging Accessories Having a 40,000 sq. foot facility allows many advantages to our customers. If you have a large or small job, call us.

More Information

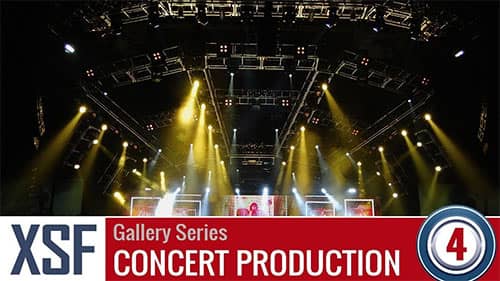

Concert Production and Lighting Truss

Episode 4

Lighting and Concert Productions Video Series – Episode 4 There are many moving parts in concert, tour and show productions. The technical expertise of the XSF crew have manged successful productions across North America

We are proud to have served so many shows over the years. Marvel Universe Live, Def Leppard, Rush, Metallica, Ringling Brothers, just to name a few. All Truss Products, staging Chain Hoists and all the rigging equipment and accessories in-between XSF continues to support shows across the USA.

More Information

Rigging and Truss Fabrication and Innovation

Episode 5

Integrated Rig Point

https://www.xsftruss.com/rigging-truss-integrated-rig-point-product

Protective Bolt Plate

https://www.xsftruss.com/protective-bolt-plate-box-truss/

ConneX Tool-less Indexable Forkends

https://www.xsftruss.com/indexable-forkends-truss-system-connex/

M.A.V. (moving lights, audio, video)

https://www.xsftruss.com/lighting-automation-video-mavtruss/

Vertical Rigging Plates

https://www.xsftruss.com/vertical-truss-rigging-plate/

UV Light Towers

https://www.xsftruss.com/uv-lights-disinfection-towers/

UV Disinfection & Sanitization Cabinets

https://www.xsftruss.com/uv-sterilizer-disinfection-cabinet-information/

Events, Trade Shows, Museums and More – Episode 6

The last in our 6 episode series, looks at events, trade shows, museums, amusement parks, corporate shows and more To see the complete series of XSF Gallery Video visit the XSF website and blog. https://www.xsftruss.com/blog/ Some of the features in this Video are: -The Guggenheim Museum -AT & T Stadium, formerly Cowboy Stadium -American Gladiators -Las Vegas Tradeshows, Restaurants, Casinos, Bars -Toyota and Volkswagen Corporate Events -6 Flags Amusement Park -The Masters Golf Tournament -Texas Raceway and more.

From Box Truss to Triangle truss in steel and aluminum, configured in circles, ovals, grids, and catwalks, XSF manufactures and fabricates to the client needs and job requirements. Support Tower Systems, Ground Support Towers, Steel or aluminum bases and more. All manufactured to meet the highest and strictest industry standards.

Additional Information

MEDIA & MORE – OTHER PLACES WE”VE BEEN

Criss Angel Mindfreak Stage Truss

XSF and Mindfreak, Criss Angel have teamed up in Las Vegas, Nevada to deliver an amazing magic and illusions show. Performed at Planet Hollywood and featuring 75 crazy Mindfreak illusions that will have you jumping out of your seat. To do such a mind-bending magic act requires precision and expertise. In this video Criss talks about the importance of the rigging and staging equipment in the show and how he could only rely on one custom truss and fabrication company to get it right…..XSF Truss. Features of the show include: 9 black powdered “finger” Truss Spans over the audience. Over 900 linear feet of truss and video panels. Over a half a billion pixels of video Custom Vertical and horizontal Truss columns on and off stage.

More Information

https://www.xsftruss.com/criss-angel-mindfreak-staging-and-truss-2019-2020/

Rock The Desert Roof System

XSF was hired by the staff at Rock the Desert to design, manufacture and oversee the installation of a large outdoor roof system that would be permanently installed for the main stage area. The main stage roof measures 140 foot wide by 40 foot deep with a trim height of 35 feet.

The performance area measures 60 foot wide by 40 foot deep with PA wings on either side of the stage measuring 40 foot by 40 foot that also include VIP seating.

The roof system includes a permanent corrugated metal skin on top and meets the engineering requirements to withstand 90 miles per hour wind loads for that region.

More Information on Roof Systems

The Economic Report with Greg Gumbel

In the ever changing world of business an organizations success depends on constantly meeting new challenges and adapting to the market place. I’m Greg Gumbel. From Ecommerce to investing strategies to human resources, join me as we take a closer look inside the workings of the modern global economy.

Welcome to The Economic Report featuring Xtreme Structures (XSF) and Feld Entertainment. Innovation plays a significant role in driving business, which in turn, drives our economy. This story exploress how Xtreme Structures (XSF) is using innovation to do just that.

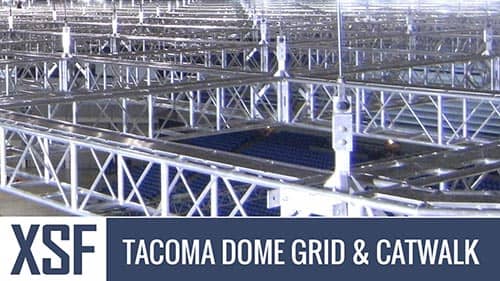

Tacoma Dome Truss Grid & Catwalk System | Time Lapse

In 2007, XSF partnered with Atlanta Rigging, Athletic & Performance Rigging, and Entertainment Structures Group to design, fabricate and install the new truss grid at Washington’s Tacoma Dome

The truss grid contains a catwalk surface and fall protection throughout the entire grid. Trim height is 81′ above the concrete slab floor.

At over 400′ long it is the largest truss grid of it’s kind in the world. The grid is engineered to support hundreds of thousands of pounds of show live loads.

More Information

https://www.xsftruss.com/arena-installations/

Guggenheim Museum Ellipse Truss Test Fit

This is the test fit for Tier 4 of an aluminum truss project for The Guggenheim Museum in New York City. The exhibit is James Turrell’s “Aten Reign” which was the most visited exhibit in Guggenheim history.

This is one of 7 ellipse rings erected to form a 70 foot tall cone structure that filled the atrium space of the museum.

More Information

Some Media and some moments .

This is a fine collection of videos that really shows why we love doing what we do. The experiences, the people, and the customers allow us the wonderful opportunity to build new structures and meet great people.

UVSD CABINETS & TOWERS – FIGHTING COVID19

Excellent Safe Solutions for Office Suites, Classrooms, Government Offices, and More.

The UV light towers and cabinets are an excellent solution in the fight against COVID19. These USA-made units are used in the sanitization and disinfection of all surfaces in rooms such as office suites, classrooms, government courtrooms, jail cells and many other enclosed area rooms.

This Device Only Does 1 Thing… Prevents the Spread of Covid19

Manufactured in Texas XSF proudly offers UV Light Towers in the Fight Against Covid19 UV Light Towers are perfect disinfection and Sanitation Solution for: • Convention Halls / Hotels • Community Centers • Hospitals / Nursing Homes / Assisted Living • County Offices / City Offices / Notary Republic Offices • Courtroom / Government Offices / Jail Cells The XSF UV Light Tower are sturdy aluminum towers that provide peace of mind by disinfecting surfaces in rooms or enclosed areas.

More Information

How to Operate the UV Light Tower | Base Model

How to Operate the UV Light Tower Base Model (UVLT-B) Learn more about this product at: https://www.xsftruss.com/uv-lights-disinfection-towers/ Operational Instructions: We ask that you get additional information on this product before operating to ensure all safety guidelines. 1. Plug in the UV Light Tower to a power supply source 2. Flip the red switch to Reset and ensure the red light is on 3. Evacuate the area to avoid UV-C exposure to skin and eyes 4. Press the UP arrow on the remote to turn the lights ON 5. Press the DOWN arrow on the remote to turn the lights OFF 6. Ensure that the lights are off before re-entering the area.

More Information

How to Operate the UV Light Tower

The UV light towers are an excellent solution for the sanitization and disinfection of all surfaces in rooms such as office suites, classrooms, government courtrooms, jail cells and many other enclosed area rooms.

In this video XSF provides the instructions for the safe operation of the UV Light Tower Timer Model. If you would like more information on this product UV Light Cabinets or any other products we encourage you to visit xsftruss.com The XSF UV Towers are a perfect disinfection solution for our large facility. The units are extremely well made and easy to operate. Lonnie Fox, County Civic Center Manager In this video you will learn how to operate the XSF UV Light Tower Timer Model.

More Information

UV Light Towers | Room Disinfection & Sanitization

Manufactured in Texas XSF proudly offers UV Light Towers in the Fight Against Covid19 UV Light Towers are perfect disinfection and Sanitation Solution for: • Convention Halls / Hotels • Community Centers • Hospitals / Nursing Homes / Assisted Living • County Offices / City Offices / Notary Republic Offices • Courtroom / Government Offices / Jail Cells UV-C technology has been proven to kill up to 99.9% of key pathogens including Coronavirus

USER TESTIMONIALS – “We wanted to keep COVID out of our workspace/office and the UV Towers are an excellent tool in the fight against this terrible virus.” Andy Endsley County Fire Chief

More Information

UV Sterilizer & Disinfection Cabinet | How to Use the XSF-UVSD-04

The XSF UV Sterilizer and Disinfection Cabinet (UVSD) is a portable cabinet equipped with UV-C lights that kills up to 99.9% of bacteria and germs on items placed in the cabinet in minutes. The UVSD includes hanger bars and hooks to suspend items for full 360-degree disinfecting. Contact us at 903-438-1100 You can also learn more at: https://www.xsftruss.com/uv-sterilizer-disinfection-cabinet-information/ The XSF UVSD kills up to 99.9% of the following key pathogens potentially transmitted via respiratory droplets in 5 minutes: Covid19 – Coronavirus* Mycoplasma (pneumonia) Staphylococcus Aureus (Staph Infection) Influenza – A (flu) And Many More.

More Information

https://www.xsftruss.com/uv-sterilizer-disinfection-cabinet-information/