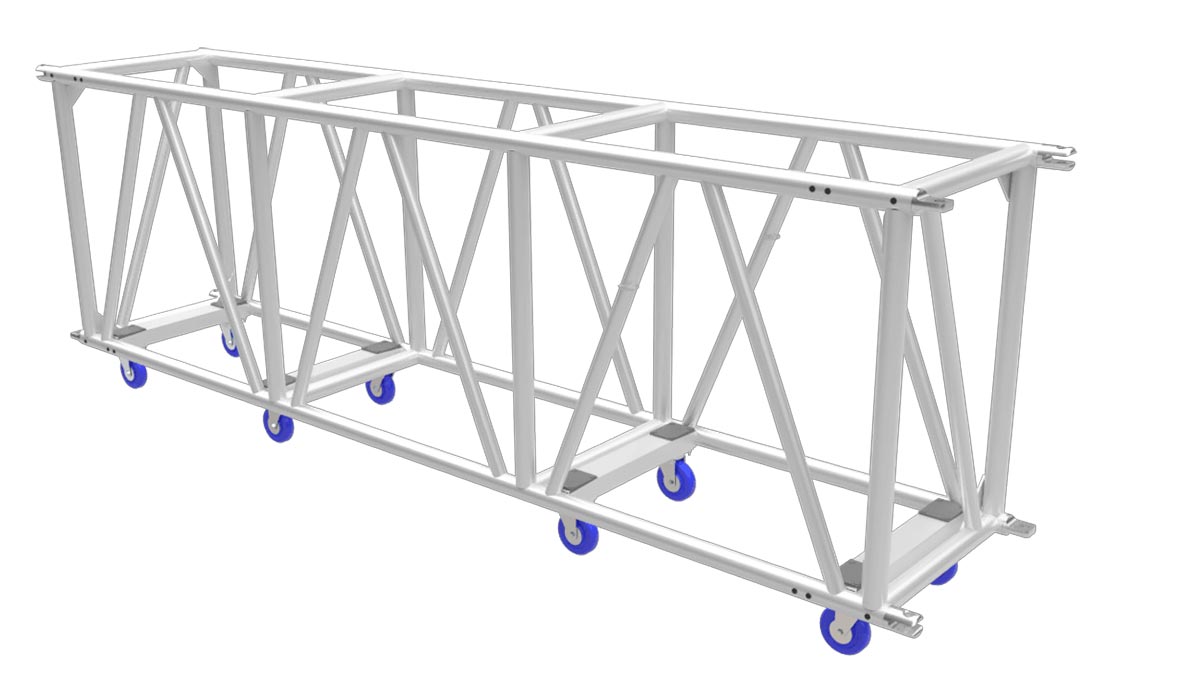

PRE-RIG GRID TRUSS

Built for Speed, Space, and Simplicity.

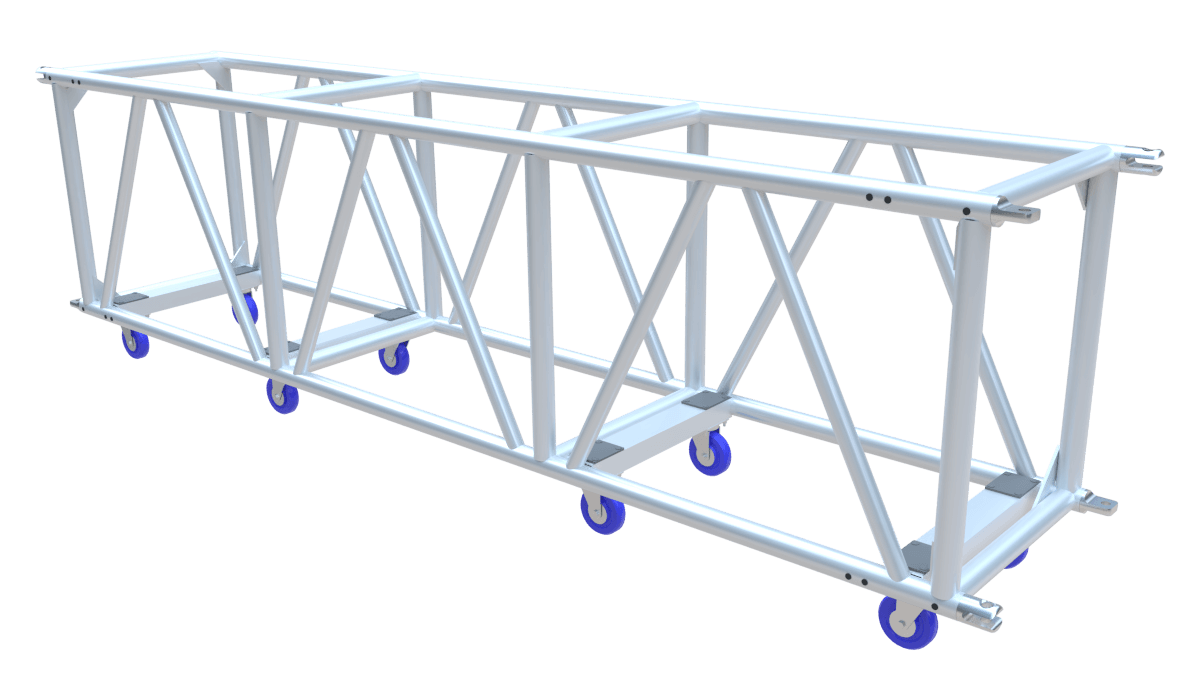

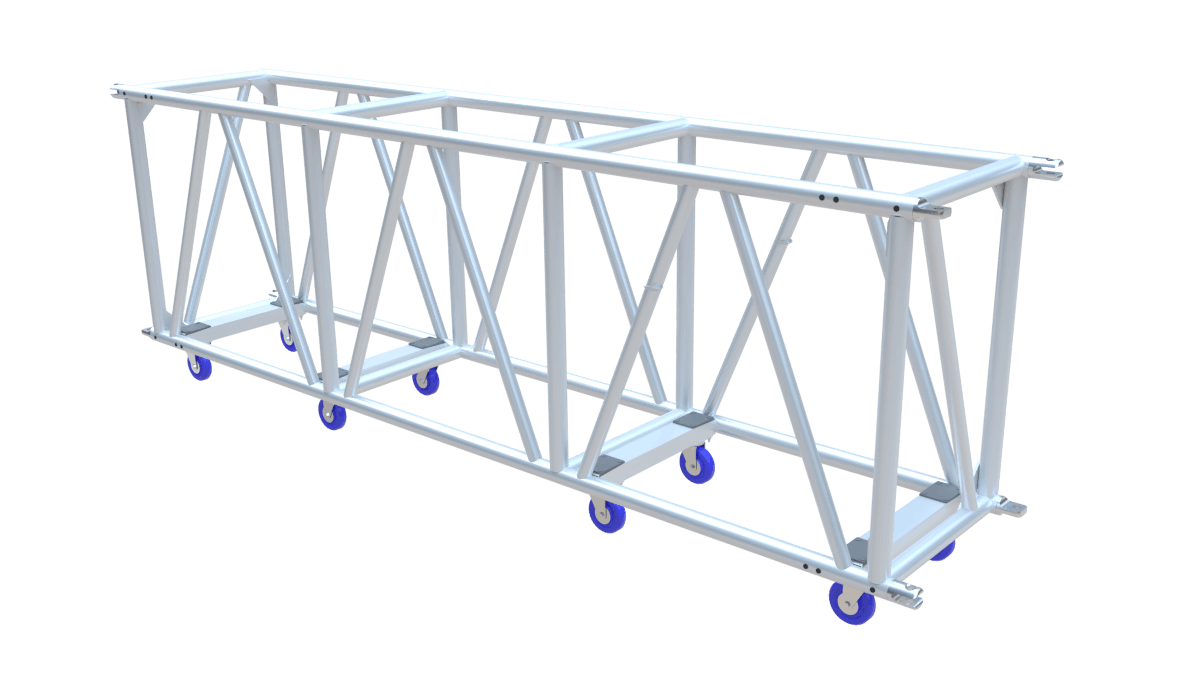

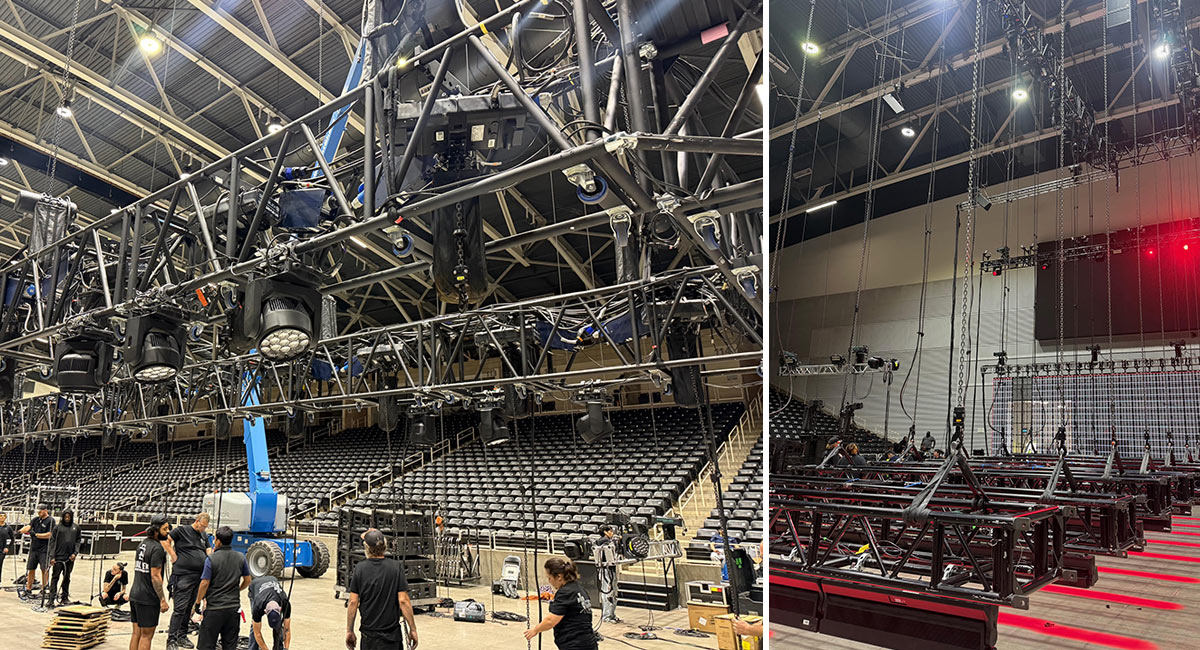

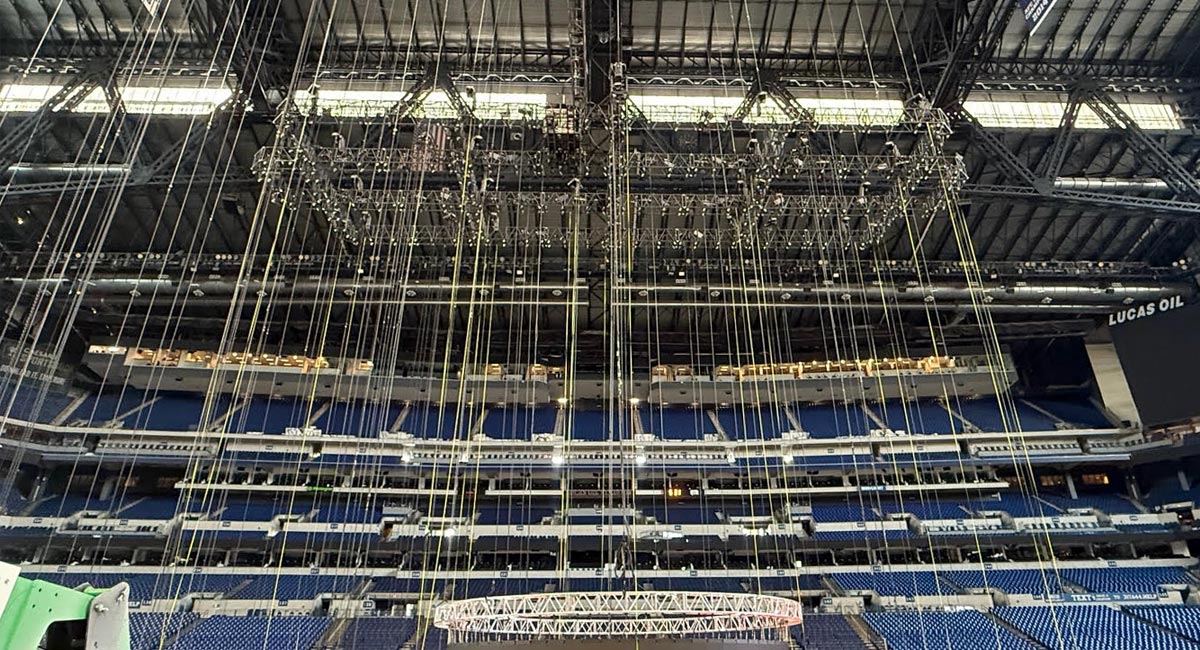

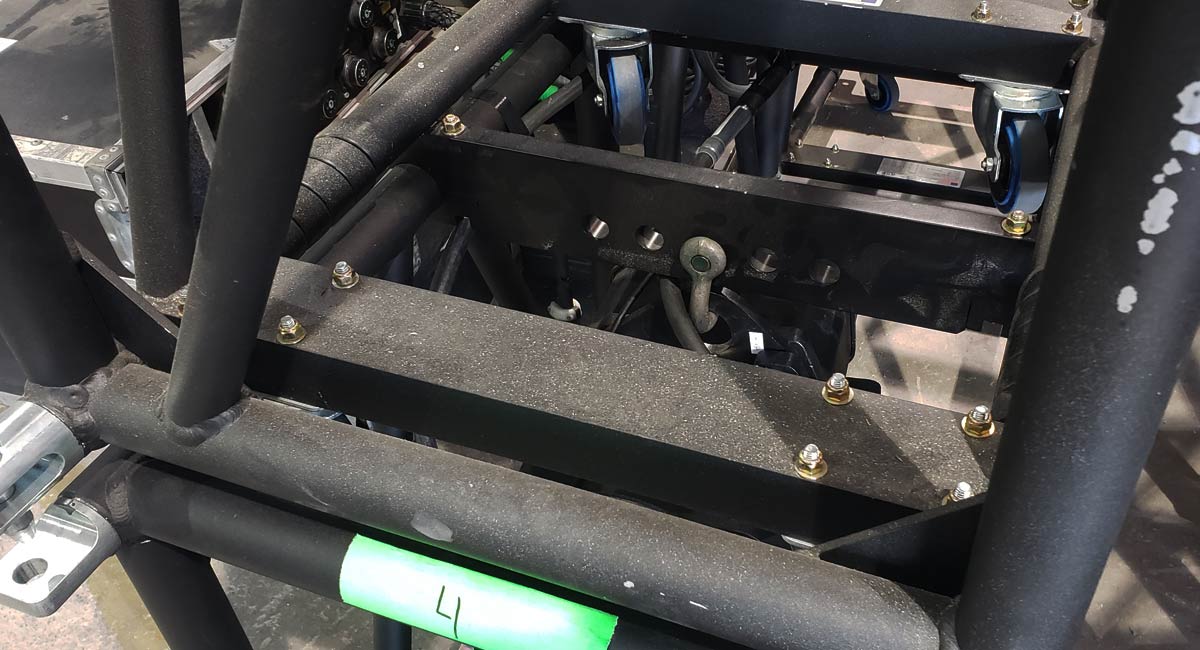

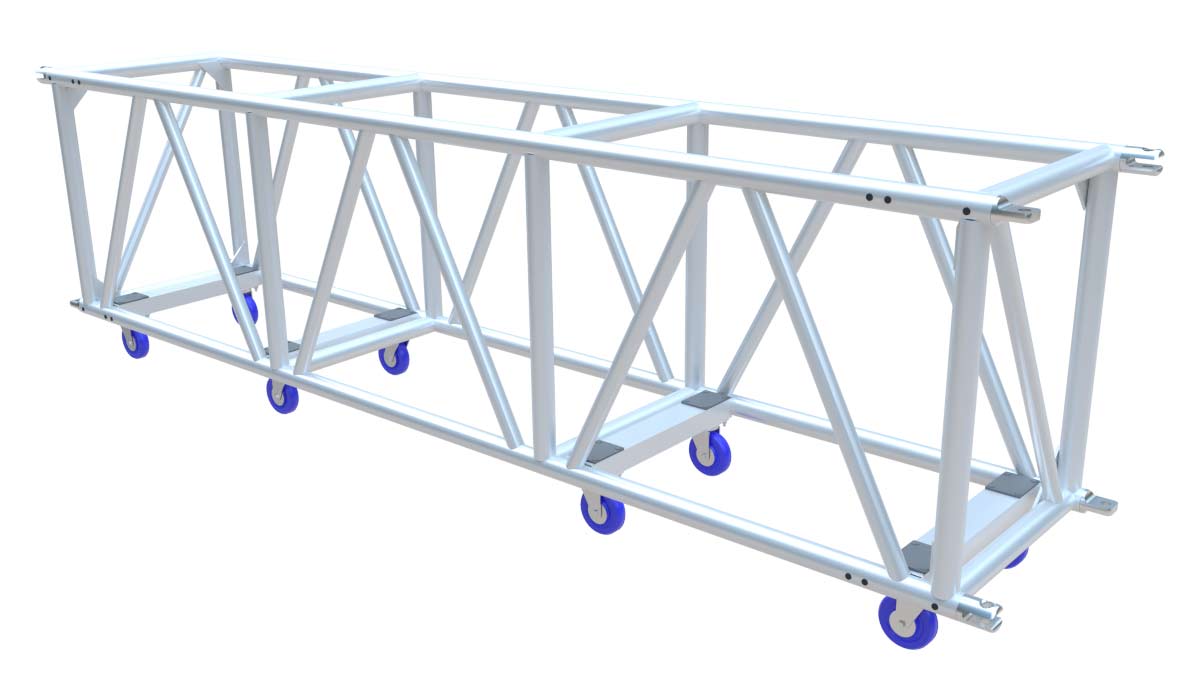

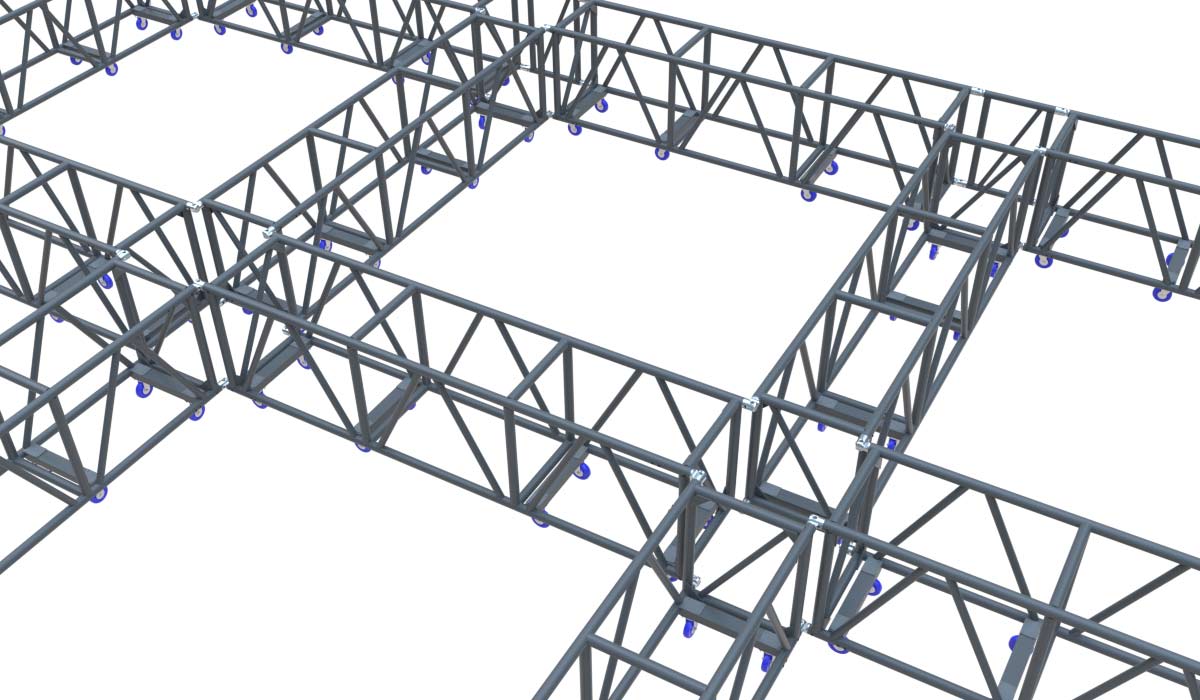

When time is tight and, or space limited, XSF’s Pre-Rig Grid Truss may help and provide a smart edge. Designed with your crew in mind, this truss helps speed up load-in and setup, reduces transport space, and simplifies your grid build. One of the key features is the convenience of pre-rigging your chain hoist motors directly into the truss before it even gets to the venue. This makes transportation more efficient and keeps your setup very streamlined. No separate storage cases for motors, no extra hardware to track down on show day. Just roll it in and you’re already ahead of schedule.

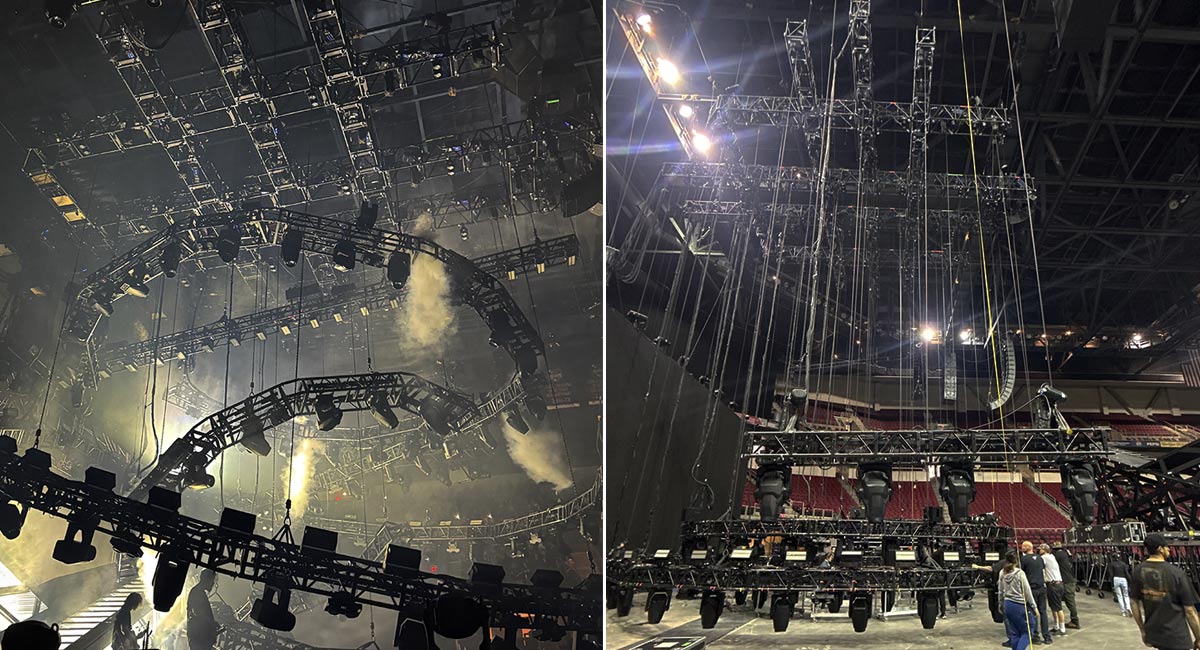

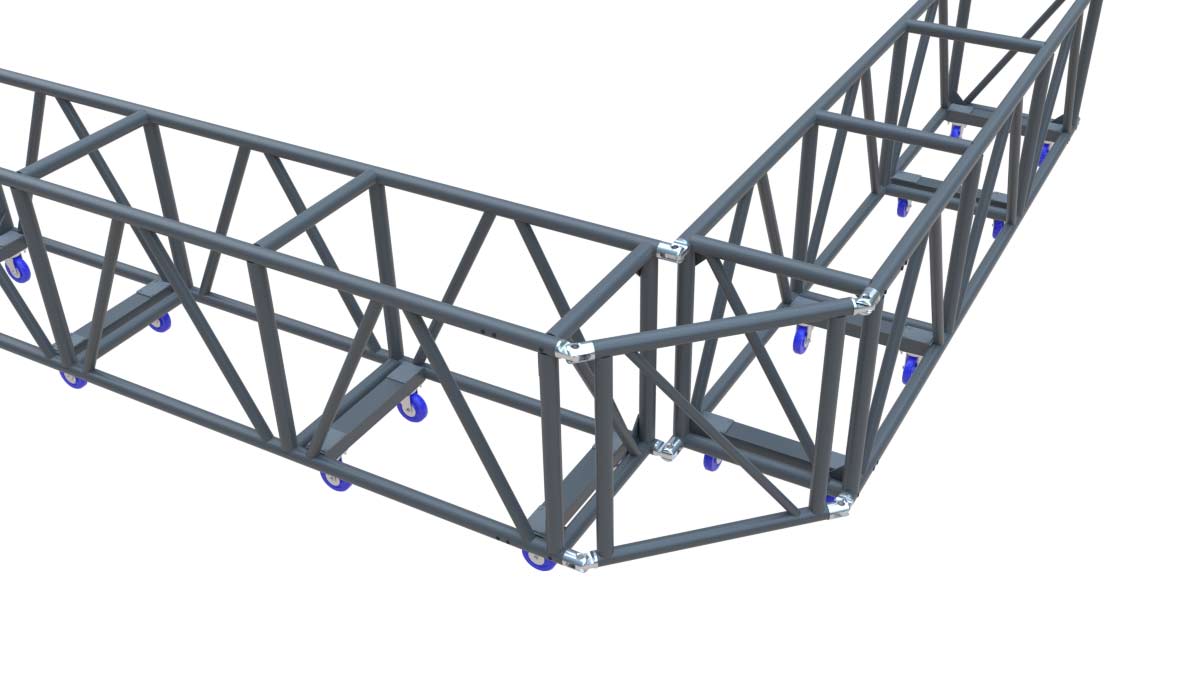

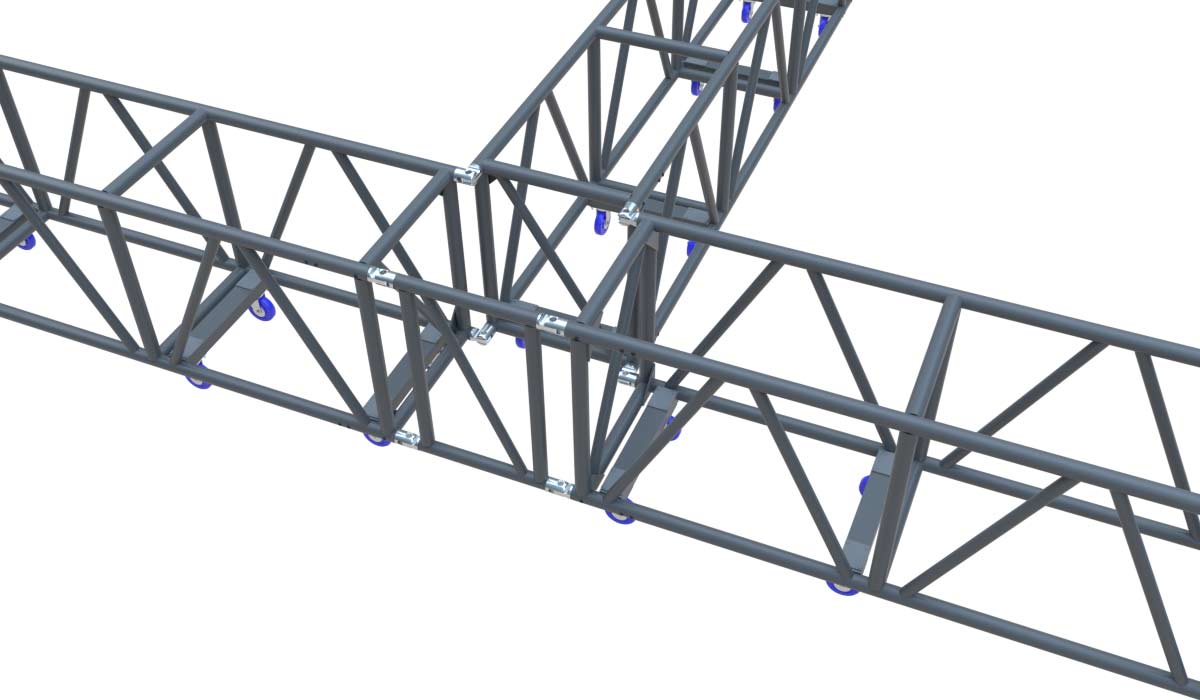

The name says it all: “Pre-Rig” for the motor-ready design, and “Grid” because the trusses connect together without the need of corner blocks. This means you can build a tidy, complete truss grid faster and with fewer parts. The truss saves you time, saves you space, and reducing effort. The Pre-Rig Grid Truss is ideal for touring rigs, permanent installs, large-scale events, and many other applications. It is product built to make a project workflow easier.

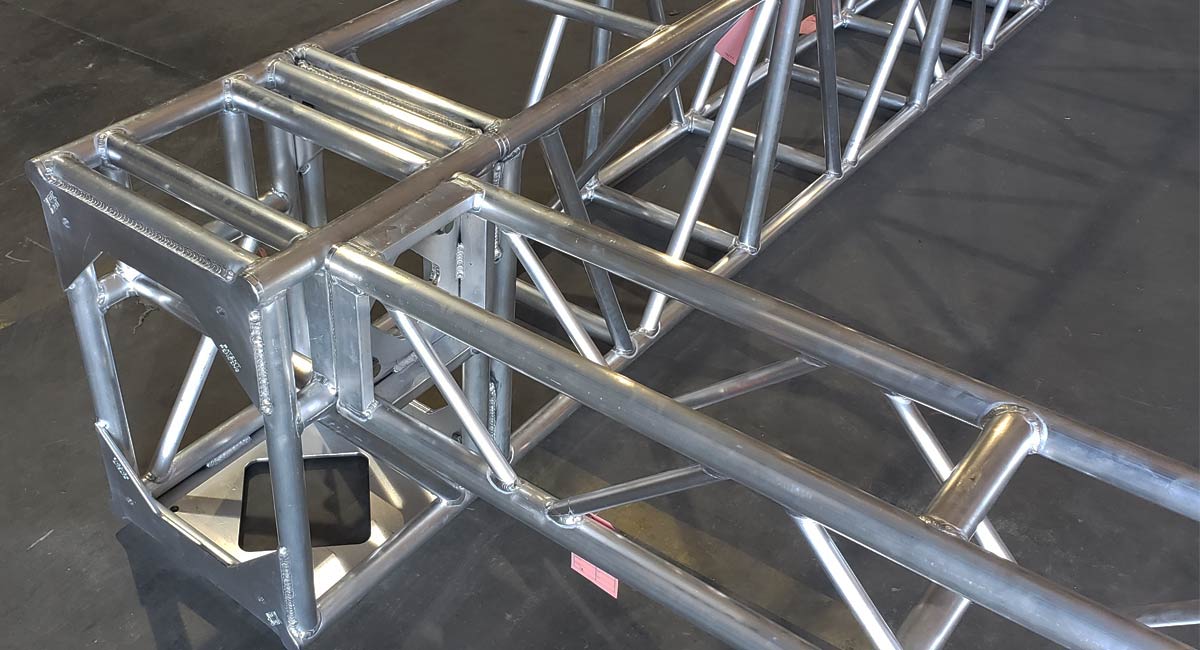

Every XSF Pre-Rig Grid Truss is fabricated in the USA by AWS-certified welders using high-strength aluminum and steel components. Steel fork ends with 3/4″ clevis pins ensure secure connections, and finishes like powder coating or anodizing are available in a vast number of colors. Call us to learn more about XSF Pre-Rig Grid Truss.

Pre-Rig Grid Gallery, Sizes and Load Tables below.

Now Available: Free XSF Truss Catalog

Download our FREE PDF catalog featuring detailed specifications, product options, and configurations for our industry-leading aluminum truss systems. This comprehensive guide covers our standard and custom truss solutions—designed for concerts, staging, lighting, rigging, exhibits, and structural applications.

Download XSFTruss CatalogSend download link to: |

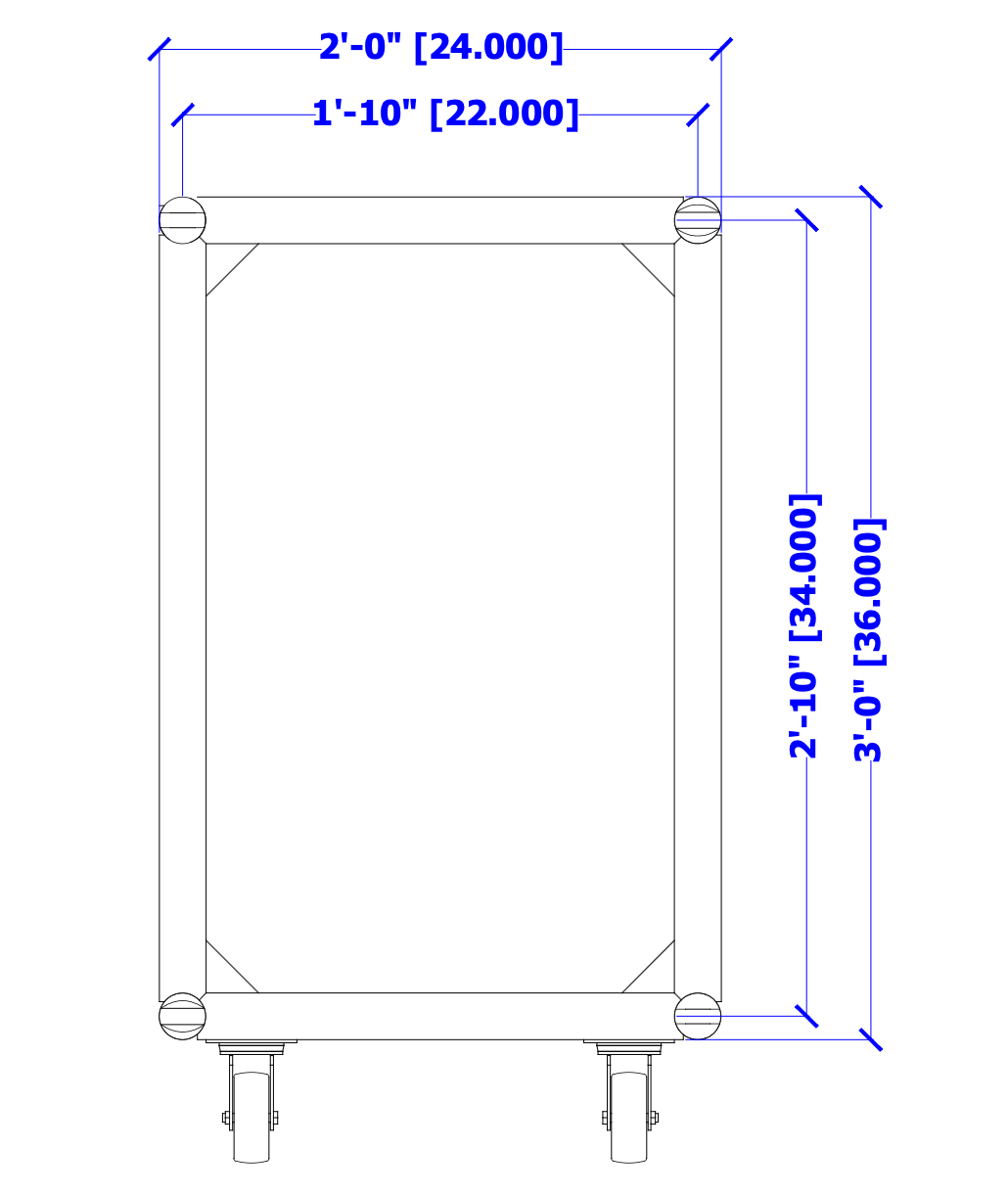

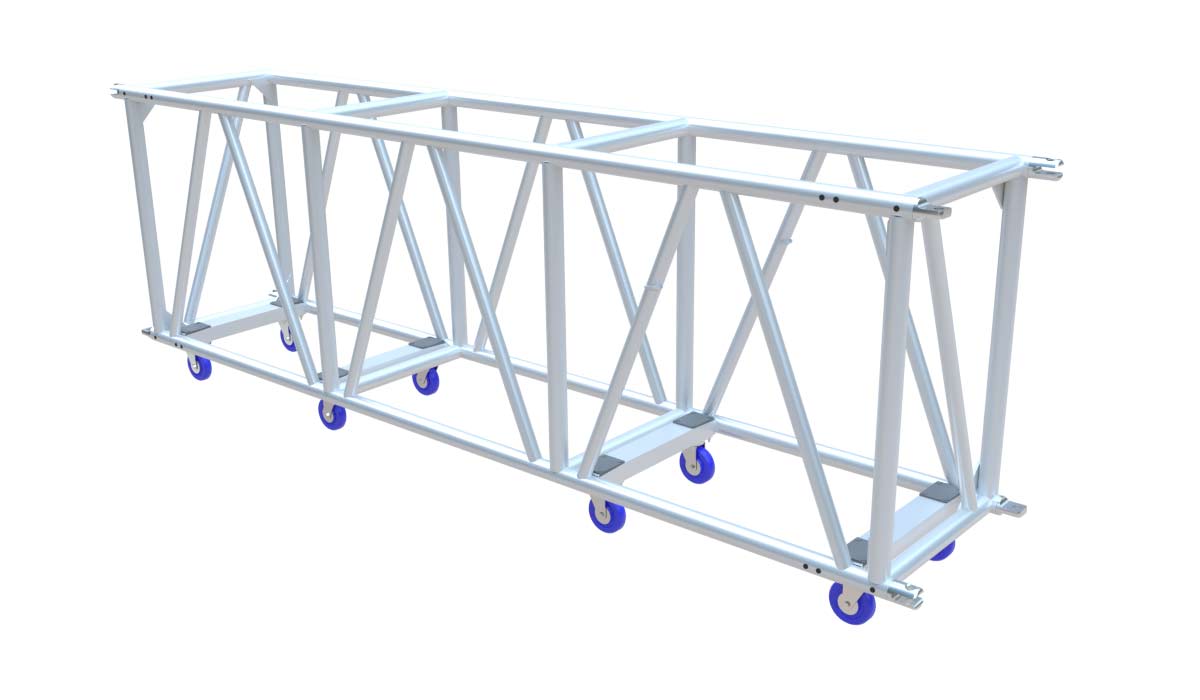

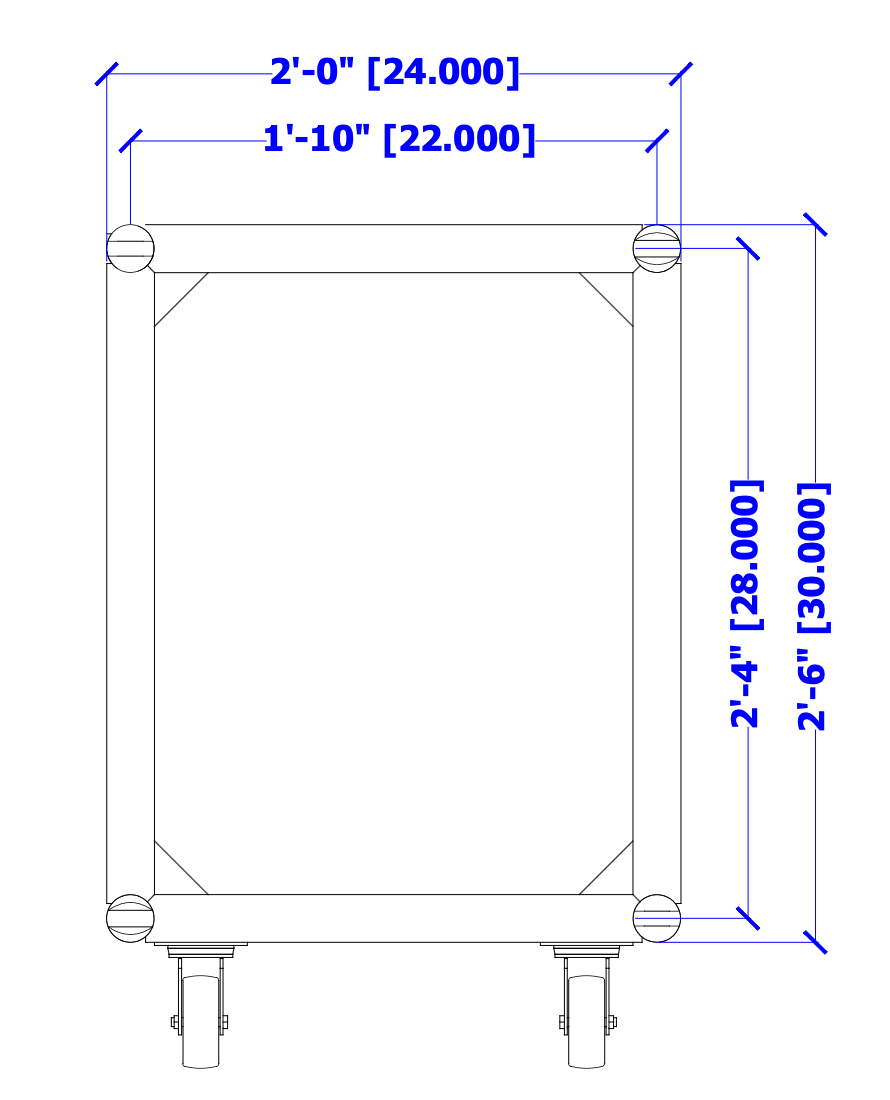

30″x 24″ Pre-Rig Grid Truss with Steel Fork Ends

30″x 24″ Pre-Rig Grid Truss with Steel Fork Ends comes in standard lengths of 5′, 8′, and 10′ with custom lengths available upon request.

The aluminum chords are 2″ OD x 3/16″ thick with 1.5″ OD x 1/8″ thick aluminum diagonals.

Forkend connections are indexed 90deg to a horizontal configuration

The trusses are joined together with 3/4″ steel clevis pins through 2″ OD steel fork end connections.

Fabricated by AWS certified welders in the USA.

Powder Coating available upon request in most colors.

Anodizing available upon request in select colors.

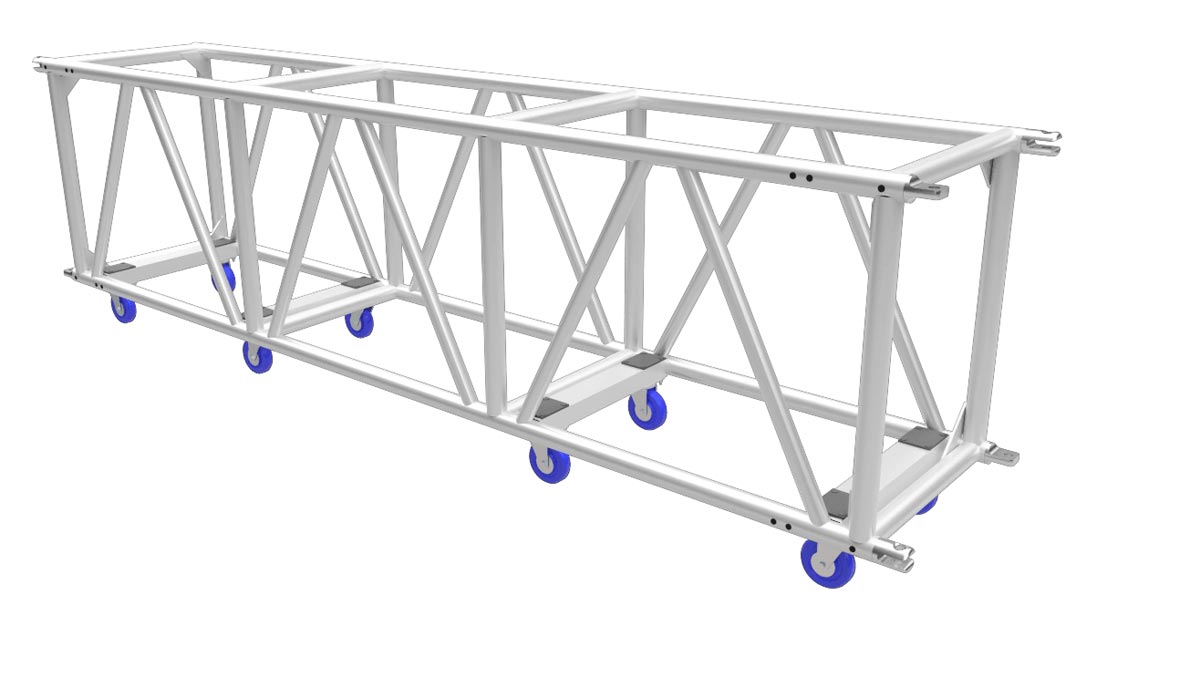

36″x 24″ Pre-Rig Grid Truss with Steel Fork Ends

36″x 24″ Pre-Rig Grid Truss with Steel Fork Ends comes in standard lengths of 5′, 8′, and 10′ with custom lengths available upon request.

The aluminum chords are 2″ OD x 3/8″ thick with 1.5″ OD x 1/8″ thick aluminum diagonals.

Forkend connections are indexed 90deg to a horizontal configuration

The trusses are joined together with 3/4″ steel clevis pins through 2″ OD steel fork end connections.

Fabricated by AWS certified welders in the USA.

Powder Coating available upon request in most colors.

Anodizing available upon request in select colors.