FINISHING TOUCHES – INSPECTION, CLEANING & COATING

In manufacturing, the final touches can make all the difference. At XSF, we take pride in ensuring that every truss is inspected, cleaned, and finished to perfection before it reaches our customers. In Part 4, we’ll explore how these steps ensure every product leaving our facility is ready to perform flawlessly.

Polished to Perfection: XSF Excellence in the Details

Cleaning and Inspection

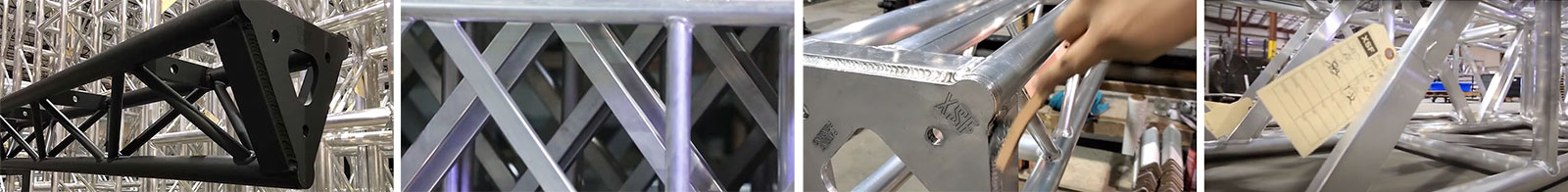

The completed truss are now moved to the shipping and receiving area for a final cleaning and quality control check. Here,welds are cleaned and checked prior to their packaging. Finish truss are carefully stored and stacked in a clean and uncluttered area of our warehouse. Again …personnel sign and date the quality control tag attached to the truss.

The final cleaning and inspection process is vital to upholding our industry-leading quality standards.

Precision Cleaning: Welds are cleaned and carefully inspected for any imperfections.

Visual & Structural Review: Each truss is given a thorough final inspection to ensure no defects or inconsistencies.

Organized Storage: Once cleared, trusses are moved to a clean and uncluttered storage area, ready for finishing.

Coating and Surface Finishes

Coating and surface finishes are not applied to any product prior to another final inspection. Preparations of this for all products, uses a specific chemical process which flushes out or neutralizes all corrosive material. Once coating or surface finish are complete they are again compared to the fabrication drawings to ensure the original design intent has been met. Any deficiencies of peeling, incorrect color, or damages that in any way do not meet the intent of the design drawings are reported to the shop foreman.

A professional finish isn’t just about looks—it’s about durability and long-term performance.

Final Pre-Coating Check: No coatings or finishes are applied until the truss has passed another final inspection.

Surface Prep: A specialized chemical process neutralizes corrosive materials, ensuring a smooth and long-lasting surface.

Design Accuracy: Every finished truss is compared against fabrication drawings to confirm it meets the original design intent.

Defect Reporting:Any issues—such as peeling, incorrect color, or damages—are immediately flagged and corrected before shipping.

Why This Matters

These finishing touches don’t just make our trusses look great—they ensure structural integrity, longevity, and peak performance.

Every XSF truss is built to withstand the demands of live events, staging, and installations while maintaining a sleek, professional finish.

What’s Next in PART 5?

In the final installment of this series, Part 5, we’ll cover the last critical step: packaging and shipping.

Learn how we ensure every truss arrives safely and ready to use.

XSF Innovations & Truss Drawings Library

See how XSF is changing the Truss Industry one innovation at a time.

ConneX allows users to change truss fork-end configurations simply and within seconds. Learn more >

The Protective Bolt Plate Truss extends the life of your truss by preventing damage – Learn more >

MAV Truss is specifically designed for moving lights, audio, and video walls. – Learn more >

Visit the XSF TRUSS DRAWINGS LIBRARY

Solidworks | Vectorworks | AutoCad | DAE | Sketch up | Blender | STL

XSF Quality Control Video at YouTube

A behind-the-scenes look at our facility and offers even more insights into how XSF maintains the highest standards for its customers.