SHIPPING PERFECTION – PACKAGING & DELIVERY

The journey from raw material to finished truss is a long and meticulous process, but it doesn’t end once the product is built. At XSF, we know that the way a truss is packaged and shipped is just as crucial as its design and construction. A product is only as good as its condition when it arrives at your door.

In Part 5 of our Quality Control Series, we’ll explore the final steps of the process—identification, packaging, and delivery—ensuring that every truss reaches its destination in perfect condition, ready to perform.

The Final Step: Carefully Labeled, Packaged, and Reliably Delivered

Identification and Packaging

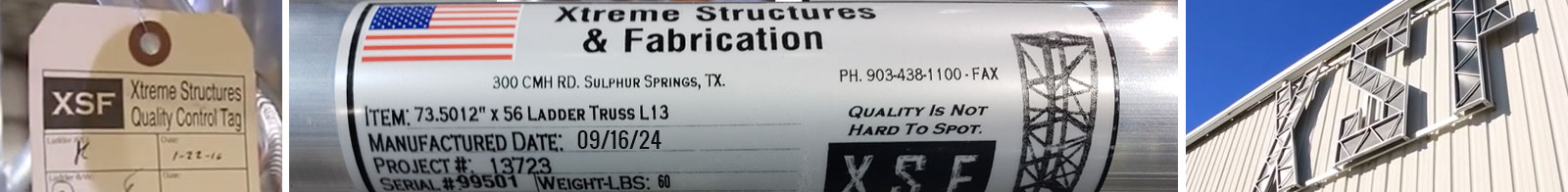

Ensuring that every truss is clearly labeled and securely packaged is an essential part of our quality control process. Each product leaving our facility is prepared for transport with precision and care, so that it arrives ready for immediate use.

- Each truss is marked with a unique XSF brand sticker, which includes essential identifying details such as serial numbers, manufacturing dates, and project-specific information. This ensures that every product is traceable and verifiable upon arrival.

- Packaging is customized for maximum protection during transport. Trusses are fitted with protective corners, shrink wrap, and custom pallets, depending on the shipping method and customer requirements.

- For large or complex orders, we go the extra step by grouping related components together to streamline on-site installation for our customers.

By carefully labeling and protecting every truss, we make sure that setup is smooth and hassle-free when it reaches its final destination.

Shipping with Care

The way a product is shipped can mean the difference between a truss that arrives in top condition and one that suffers damage in transit. That’s why no chances should be taken when it comes to shipping.

- We work with trusted freight partners to ensure that each shipment is secured, tracked, and delivered efficiently. For customers who prefer to use their own shipping providers, we accommodate their logistics while still applying our strict packaging and quality control measures.

- Every truss is securely strapped, labeled, and prepared for transport to withstand long-distance travel and various handling conditions. No detail is overlooked, from the moment the product leaves our facility to its final destination.

- We provide clear documentation with every shipment, allowing customers to quickly verify their order and check specifications upon arrival.

By prioritizing secure packaging and reliable delivery methods, we help ensure that our customers receive their trusses on time and in excellent condition, ready for immediate use.

Why This Matters

As you have likely learned trusses alone do not define what XSF Truss does; it’s the craftsmanship, engineering, and dedication behind them that set the standard From the first weld to the final inspection, every step in our 9-step Quality Control Process is focused on ensuring that our products meet the highest standards. Shipping and packaging are no exception.

- Proper labeling ensures accuracy and efficiency for our customers.

- Secure packaging prevents costly damage and delays.

- Reliable shipping ensures that customers get what they need, exactly when they need it.

When an XSF truss or innovative products arrives, customers can trust that it’s built to last, built to perform, and built for success.

Final Thoughts

Thank you for joining us on this journey through the XSF Quality Control Process.

This 5-part series has explored the precision, craftsmanship, and expertise that go into every truss we manufacture.

If you’d like to see these steps in action, check out our XSF Quality Control Video on YouTube.

Need support for your next project? Explore the full range of services and application expertise that XSF brings to every job. Whether it’s custom fabrication, stage rigging, or structural solutions, our team is ready to deliver excellence you can always trust.

XSF Innovations & Truss Drawings Library

See how XSF is changing the Truss Industry one innovation at a time.

ConneX allows users to change truss fork-end configurations simply and within seconds. Learn more >

The Protective Bolt Plate Truss extends the life of your truss by preventing damage – Learn more >

MAV Truss is specifically designed for moving lights, audio, and video walls. – Learn more >

Visit the XSF TRUSS DRAWINGS LIBRARY

Solidworks | Vectorworks | AutoCad | DAE | Sketch up | Blender | STL

XSF Quality Control Video at YouTube

A behind-the-scenes look at our facility and offers even more insights into how XSF maintains the highest standards for its customers.