What are Aluminum Truss and Rigging Accessories?

Truss and Rigging Accessories Overview

Truss and rigging accessories play a crucial role in the functionality, safety, and versatility of any rigging, staging, and truss system. From rigging points and stacking aids to mounting plates and transport solutions, each component is designed to solve specific challenges faced in real-world production environments.

Whether it’s creating stable overhead connections, enhancing structural alignment, or improving setup and teardown efficiency, these accessories work together to support the demands of both permanent installations and fast-paced touring setups. This collection highlights key accessories that expand the capabilities of standard truss systems—each one purpose-built to increase reliability, simplify workflows, and adapt to a wide range of applications.

All products mentioned here are readily available through XSFtruss, proudly made in the USA and ready for your next project.

Truss Dollies

Truss dollies are essential for transporting and stacking trusses efficiently. Unlike traditional models that require manual stabilization, this dolly features a center outrigger leg, making it self-balancing. Most other dollies only have a single bar with two wheels, making stacking trusses more tedious. In contrast, this dolly’s three-wheel design keeps it level, allowing users to place it in position and drop the truss onto it with ease.

Built for heavy-duty applications, this dolly ensures maximum durability under heavy loads. It is available in various sizes, with custom options available to fit specific applications. Additionally, it can adapt to circular trusses. For example, when transporting a 10-foot diameter circular truss, only two dollies are typically needed to support it, and they can handle stacking to significant heights. Its robust construction allows it to accommodate a large volume of truss before reaching its weight capacity.

Regarding configuration, the T-bar-style truss dolly typically requires two units for a stable stack. These dollies come in different widths to accommodate various truss sizes, including 12” x 12”, 16” x 16”, and larger custom options. Customers can specify the number of trusses they need to stack side by side, and the dolly is built accordingly. The widest standard dolly can accommodate a 4-foot-wide truss load, which allows stacking four 12” x 12” trusses or two 20.5” trusses side by side.

Additionally, this dolly has been customized for other unique applications, including transporting products into large-scale powder coating ovens. This adaptability makes it a highly sought-after product, frequently ordered due to its efficiency, versatility and durability.

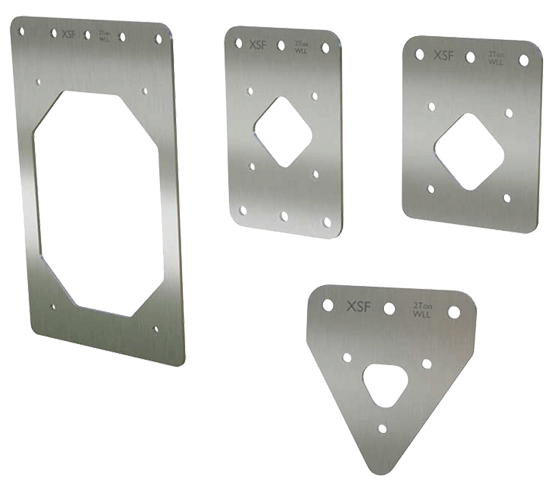

Vertical Rigging Plate

The vertical rigging plate offers a fixed, secure rigging point for truss structures, eliminating movement and rotation often seen with slings. Unlike soft rigging, it provides a stable alternative for precise rigging needs.

As a permanent and precise rigging solution, it bolts directly onto the truss at the end or joint. The plate is lightweight yet extremely strong, with a two-ton load rating, making it stronger than many clamp-on rigging points, which are typically limited to one ton.

Manufactured in-house, these plates can be customized to accommodate additional rig points, such as designs with both top and bottom rigging locations. While designed for bolt plate trusses, they are not brand-specific and can be used across different truss manufacturers, as long as the truss has a compatible bolt plate design. However, they are not intended for four-chord trusses that lack bolt plates.

One of the key benefits of this plate is its use in permanent installations, ensuring truss sections align precisely with mounting points on overhead beams. At only 3/8” thick, it maintains minimal gaps between connection points while preserving structural integrity. In many setups, trusses must be spaced at specific intervals to match beams, and this plate allows for secure, repeatable placements.

Another major advantage is fire safety. Unlike nylon slings, which are not fire-rated and may pose risks in certain environments, the vertical rigging plate is entirely metal. While it does not carry a specific fire rating, it is non-combustible, making it a preferred choice for venues where fire safety is a concern.

The choice between a vertical rigging plate and soft rigging depends on customer needs. If flexibility is required, slings may be the better option. However, for those seeking a secure and permanent rigging solution, the vertical rigging plate ensures stability and confidence.

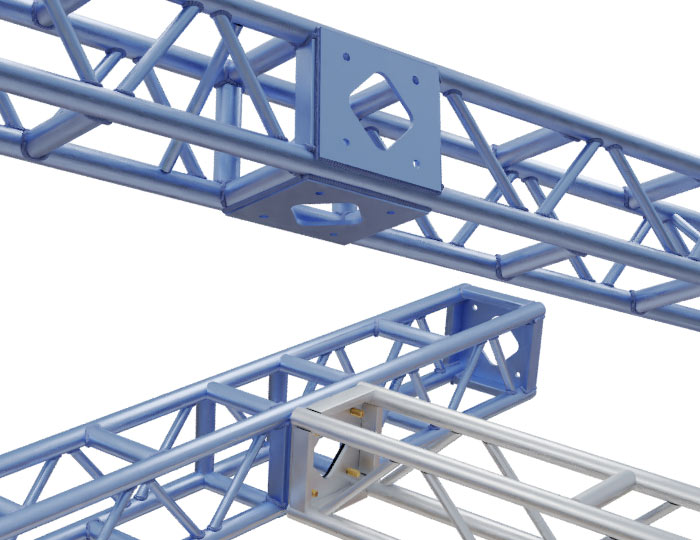

Pinch Blocks

Pinch blocks are a widely used solution for connecting trusses at a right angle and go by different names depending on the manufacturer. They are compatible with multiple truss brands and are a standard component in the industry.

This particular pinch block design is nearly identical to those sold by other manufacturers but includes an optional center-hole rig point. Some customers request a version with a bolt-through center, allowing it to be used as a rigging point for hanging equipment or securing guy wires. This modified design is popular, and additional product images showcasing this variation could be beneficial for customers.

Pinch blocks are typically used to connect two trusses perpendicularly and are compatible with both ladder trusses and box trusses. They are widely available and serve as a cost-effective alternative to traditional corner blocks. Unlike corner blocks, which require bolting trusses together, pinch blocks provide a faster and more adaptable solution.

However, pinch blocks have one limitation—while they can attach a truss at a 90-degree angle, they cannot accommodate multiple perpendicular trusses at the same point. If multiple trusses need to connect at the same height, a corner block is required instead. For example, in a trade show booth setup, a corner block would be necessary at each intersection of a 20′ x 30′ truss grid to maintain structural integrity.

Load-wise, pinch blocks are as strong as standard bolt plate connections and can handle significant weight. If a customer has an unusual load requirement outside standard load tables, an engineer may need to review the specifications.

Despite these considerations, pinch blocks remain highly popular due to their simplicity, effectiveness, and affordability. By reducing the need for corner blocks in certain applications, they provide an efficient and cost-effective way to join trusses perpendicularly, making them a staple across various industries.

Sleeve Block Adapter Kit

The XSF Sleeve Block Adapter Kit is a highly versatile and cost-effective solution for stage truss and lighting applications. Whether for a Ground Support System, Four-Post System, Goal Post, or Two-Post System, this adapter transforms a standard 4-way corner block into a self-climbing truss or grid, offering flexibility and efficiency.

Designed to save time and simplify installation, the adapter is especially useful for LED video wall structures, allowing for quick setup, easy adjustments, and improved workflow. It also enables truss grids to move seamlessly, as chain hoist motors can mobilize the entire grid once the four posts or truss towers are in place. This innovation has been well-received at industry trade shows, where professionals recognize its potential to streamline rigging and event setups.

The kit consists of eight caster wheel brackets, which bolt securely into XSF’s standard 20.5” 4-way corner blocks. This design ensures the adapter maintains the load ratings for 20.5” x 20.5” truss, creating a stable vertical guideway along a 12” x 12” standard format tower truss. Unlike traditional fixed sleeve blocks, this system allows free movement within the structure, offering greater flexibility for various rigging applications.

All XSF corner blocks and truss towers are manufactured in the USA using certified 6005A alloy for exceptional strength and durability. Powder coating is available in any color upon request to match design needs.

This adapter is a game-changer for productions, tradeshows, and live events, delivering efficiency, versatility, and cost savings for rigging professionals.

Truss Topper

Truss toppers are a simple yet highly functional accessory designed to mount lights or equipment onto truss structures. They are a versatile tool that many professionals regularly use in their setups.

The product was created to offer a simpler way to mount lighting fixtures. As a result, the truss topper has become a versatile solution for various setups.

Truss toppers offer a lightweight but strong solution for attaching fixtures to both vertical and horizontal trusses. They’re commonly used for constructing towers or mounting moving lights, which can be precisely positioned for various lighting effects.

The product renderings provide a clear view of how truss toppers are used in various setups, illustrating their practical application.

Customization is available, but many standard sizes are offered, and most users find these options sufficient for their needs. Their simplicity, strength, and ease of use make truss toppers a must-have accessory in many truss setups.

Pin Puller

The pin puller is a specialized tool designed to make removing clevis pins from four-chord trusses safer and more efficient. Clevis pins can become extremely tight under load, and traditionally require hammering to remove—an approach that carries safety risks and can result in lost or damaged hardware.

The pin puller addresses this problem with a weighted slide hammer mechanism. Its heavy handle slides along the shaft to generate enough controlled impact force to dislodge tight pins in just a few strikes.

A custom-machined, slotted steel head fits securely around the clevis pin, locking it in place. By pulling the weighted hammer down, the pin is safely removed without the risk of it becoming a projectile.

This tool is particularly useful for rigging professionals, as it reduces both the effort and injury risk involved in disassembling truss structures. The pin puller is considered an essential piece of equipment for truss assembly teams who frequently work with clevis-pin trusses.

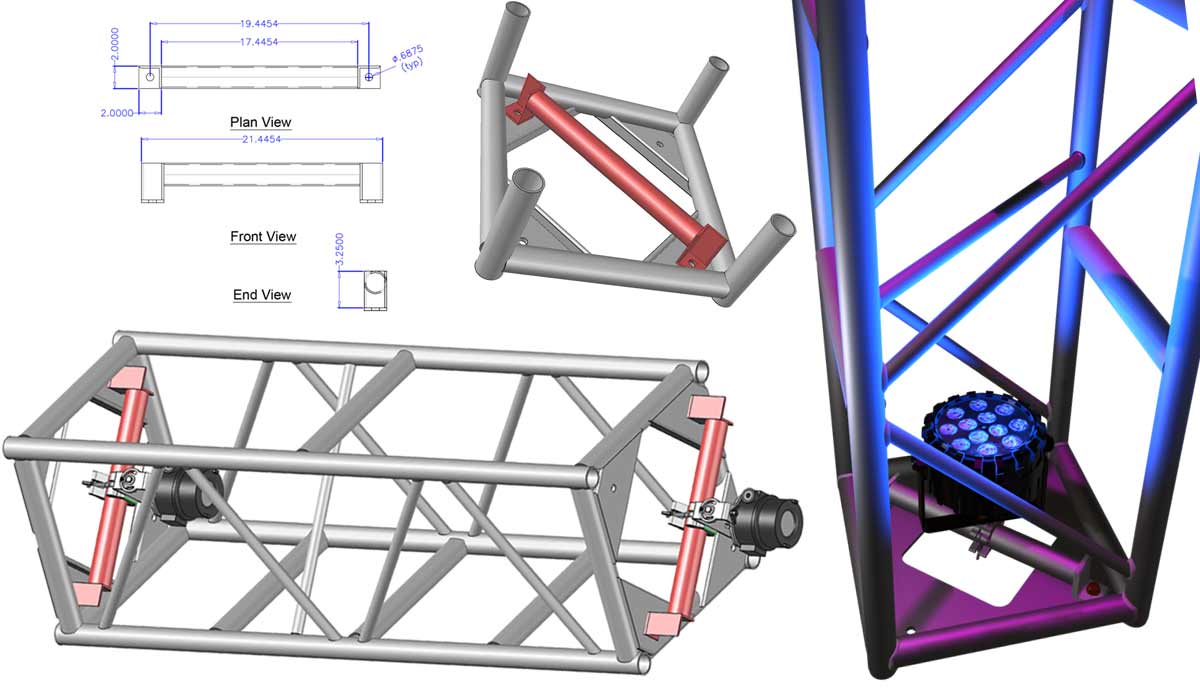

Truss Warmer

A truss warmer is a simple but effective lighting adapter designed to illuminate truss towers or truss spans using LED washes or uplights. The addition of colored lighting inside truss can significantly enhance the visual appeal of the stage or venue.

This adapter is a bolt-on solution aimed at being both affordable and easy to install. It allows users to attach lighting fixtures directly to the truss, rather than relying on floor-mounted lights with built-in bases.

Truss warmers can be used to mount colored lighting inside truss towers or along horizontal spans, creating a dynamic visual effect and offering a cost-effective way to enhance truss aesthetics in a variety of settings, including trade shows, events, and stage designs.

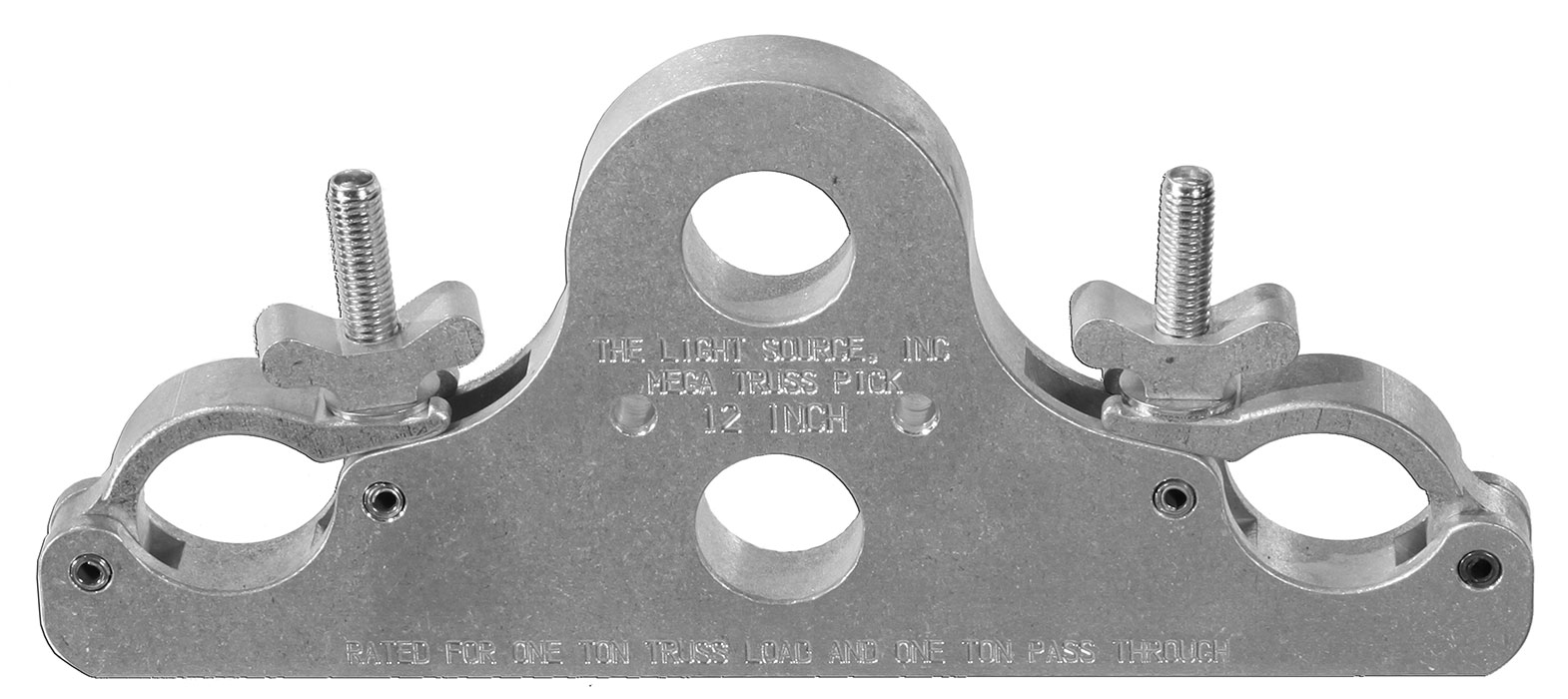

Truss Pick

The truss pick is a commonly used accessory designed to serve as a rigging point for hoisting trusses. It is an essential tool for truss rigging.

When dealing with rigging points, there are typically two options: clamp-on solutions like the truss pick or XSF’s own integrated rig points which is built directly into the truss. An integrated rig point is a permanent solution and is often used in fixed installations or when the rigging point will always be in the same location.

Because integrated rig points are a fraction of the price of clamp-on alternatives, they can be more cost-effective when the setup does not require repositioning. However, the truss pick’s biggest advantage is its flexibility.

Unlike a fixed rig point, these clamp-on models can be attached anywhere along the truss, allowing users to move it as needed. While it still requires careful placement to avoid obstructing horizontal and diagonal braces, it provides much more adjustability than a permanently affixed rigging point.

For existing truss inventory, Truss Picks are an excellent solution because they can simply be purchased and clamped right onto their trusses.

Projector Plate

The projector plate is a popular truss accessory, originally developed in response to customer demand. As projectors became more common in truss-mounted setups, the need for a secure, stable mounting method grew.

These plates provide a reliable platform, eliminating the need for makeshift solutions like ratchet-strapped plywood. The projector plate can be bolted directly to truss structures or mounted with clamps, and it supports both horizontal and vertical orientations.

Though originally designed for projectors, the plate also works well for mounting other equipment such as lighting fixtures or custom hardware. For gear without a built-in truss-mounting interface, this plate serves as a universal attachment point.

Standard sizes are available, and custom variations can be produced on request. In-house CNC machining allows for precise fabrication of custom shapes when needed.

Outrigger for Ground Support

The outrigger is a structural reinforcement component designed to increase the stability of stand-alone ground support truss systems. When truss towers or vertical columns are used in outdoor settings or exceed certain height thresholds, outriggers become essential for maintaining structural integrity.

These clamp-on supports extend outward from the truss base, effectively increasing the footprint of the structure. Without outriggers, a vertical truss column typically relies on a small square base for stability, often measuring around 18 to 24 inches.

By attaching outriggers, the base support area can be expanded to 6’ x 6’ or even 7’ x 7’, significantly enhancing the tower’s ability to withstand lateral forces.

Outriggers are particularly important for temporary outdoor installations, such as concert stages and festival setups, where wind loads and uneven ground conditions can pose challenges. By extending the truss base outward, outriggers reduce the risk of tipping and distribute the load more effectively.

Durable, easy to install, and critical for safety, outriggers are a smart addition to any ground support truss system.

Integrated Rig Points

An integrated rig point can be considered a truss accessory, even though it is more of a built-in feature than an add-on. Unlike clamp-on rigging accessories, an integrated rig point is permanently incorporated into the truss during manufacturing, making it a fixed structural element rather than a removable accessory.

This type of rig point is commonly requested in custom truss designs, particularly for installations where rigging positions need to remain consistent. Unlike clamp-on solutions, which provide flexibility by allowing rigging points to be repositioned along the truss, integrated rig points eliminate the need for additional rigging hardware.

Because these rig points are part of the truss itself, they offer a clean and streamlined, cost-effective alternative to clamp-on rigging accessories, especially in permanent setups such as theaters, stadiums, and architectural installations. Integrated rig points are less common in temporary stage productions, where modular and adjustable rigging solutions are most often preferred.

Strong, and discreet, the integrated rig points are an ideal solution when consistency and clean design are top priorities.

Side-On Plate Connection

The side-on plate connection is a simple but highly effective truss accessory, often overlooked because it is not widely advertised. It provides an alternative connection method for trusses, offering a more economical solution than using a corner block or pinch block.

This welded plate attachment is particularly useful when a perpendicular connection is needed but a corner block is not necessary. Side-on plate connections are often used on 12” x 12” bolt plate truss but can be customized for other truss sizes as well.

A single plate is cut using CNC machining and welded onto the side of the truss, creating a permanent mounting location. This eliminates the need for a corner block, helping reduce overall cost and simplifying the connection process. Unlike a pinch block, which clamps around truss chords, the side-on plate is permanently affixed, offering a stronger and more secure connection.

This solution is commonly used in custom applications, where a clean and permanent perpendicular connection is required.

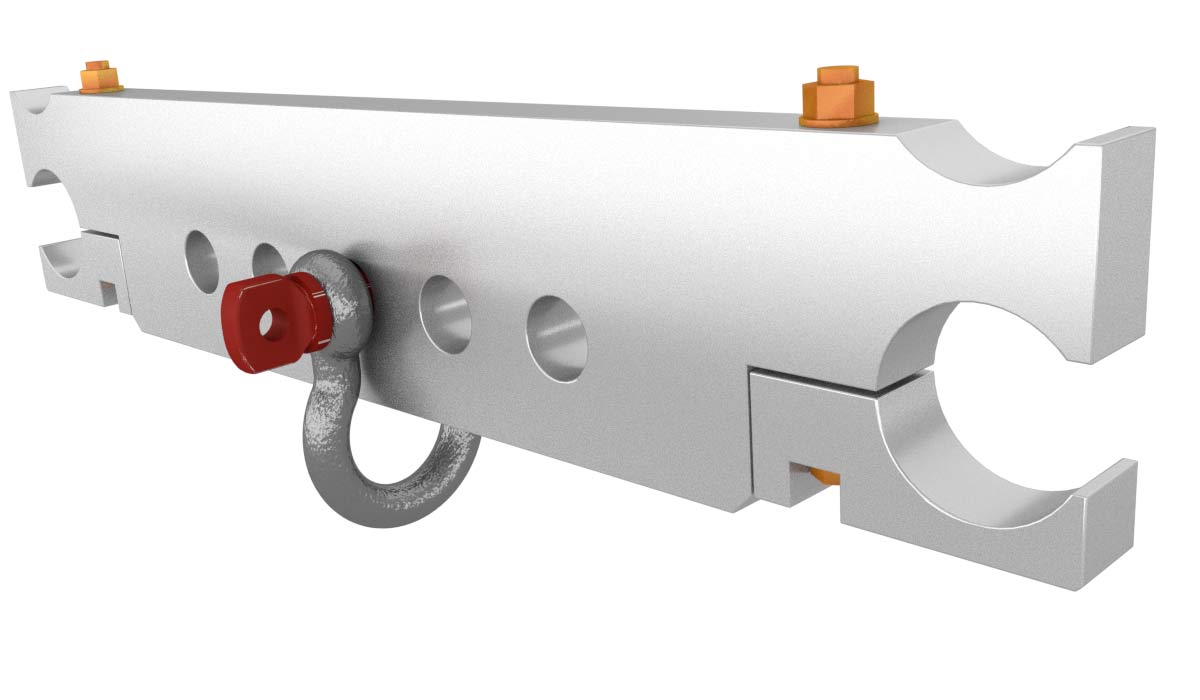

Stacking Rig Point

The stacking rig point is a unique accessory that serves a dual purpose, functioning both as a rigging point and as a truss stacking aid during load-out. Unlike some other rigging points that offer limited load capacity, this semi-permanent clamp-on point is rated at two tons, while other versions are typically rated at only one ton.

Beyond providing a secure rigging attachment, the stacking rig point also features a saddle box design that helps keep trusses aligned and securely in place when stacked. This prevents the trusses from shifting or rolling during loading and transit, reducing the risk of damage and making storage and transportation more efficient.

For customers managing large truss inventories, this accessory provides a major advantage by combining rigging functionality with stacking efficiency in a single component. While not permanently affixed, its semi-permanent design allows it to remain securely in place and still be removed when necessary.

The stacking rig point is a reliable and simple solution for both rigging and stacking needs.

Wire Rope Slings, Shackles, and Span Sets

When it comes to rigging and suspending trusses, wire rope slings, shackles, and span sets are standard industry tools. These accessories are used in various rigging configurations to ensure trusses are securely attached and properly positioned.

Wire rope slings are commonly wrapped around steel beams in venues, allowing riggers to suspend trusses securely. They can also be used as drop-down extensions, offering flexibility in height adjustments. Shackles and span sets provide strong and reliable connection points between truss structures and hoists, increasing load-bearing stability. Stack chain serves a similar function but is a heavier-duty alternative, made of thick steel links that provide greater strength and precise height adjustment. It’s often used in place of turnbuckles, allowing for incremental changes simply by repositioning the chain link.

While wire rope slings are lighter and more flexible, stack chain is stronger and provides more control over rigging height adjustments. Together, these components form the backbone of truss rigging setups, ensuring safe and secure suspension in a variety of staging environments. Reliable, versatile, and widely trusted, these tools are essential components of any professional rigging system.

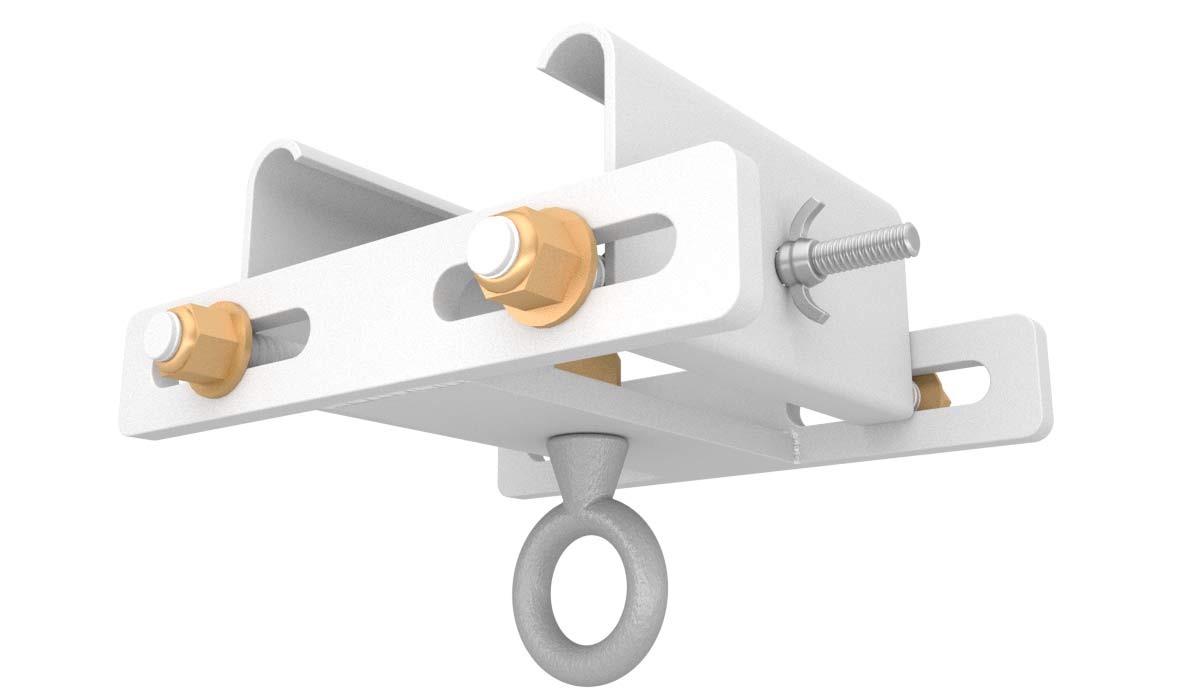

Beam Clamps

Beam clamps provide an adjustable rigging point, making them versatile for temporary installations where mounting positions may need to be changed frequently. They are readily available and widely used in concerts, trade shows, and special event setups, allowing riggers to hang lights, speakers, and other equipment directly from overhead beams.

Conclusion

These truss accessories are built to solve real problems in staging, rigging, and transport. Whether it’s making setup faster, keeping gear secure, or improving overall safety, each piece plays a part. Together or separately, they help make any truss system more reliable and efficient. XSF offers a full range of rigging and truss accessories—including vertical rig plates, sleeve block adapters, and integrated rig plates. These components are proudly made in the USA and readily available to support your next project.