Inspecting your truss annually as well as before each use to ensure a safe overhead rigging environment in your work place is of paramount important. We will cover few main points about Truss inspection in this (post/email) but we encourage you to visit the link below to further understand the inspection requirements.

Frequent inspections are defined as visual inspections to be conducted prior to each use and immediately after any incident that may have in any way caused damage to the system or truss. Records are not required to be kept for Frequent Inspections.

Initial and Frequent Inspections are visual inspections and shall be performed by a competent person with the following items inspected:

- Geometry of truss for twisting, racking or bending

- Truss members for dents, bends, abrasions, or missing members

- Truss connections for flatness or deformation

- Fastening hardware for proper grade, deformation or excessive wear

- Welds for breaks, cracks, or deformation

Any weld thought to possibly be defective shall have additional non-destructive testing performed by a qualified person. Non-destructive testing may include dye penetrant testing.

A detailed outline of the inspection requirements set forth in ANSI E1.2

can be found a

https://www.xsftruss.com/truss-inspection/ along with a video describing the same.”

Periodic inspections are defined as annual visual inspections with dated records to be kept on file with the owner.

Periodic inspections shall be performed by a competent person with the following items inspected:

- Geometry of truss for twisting, racking, bending, sweep, or camber Truss members for dents, bends, abrasions, or missing members Connection plates for flatness, deformation, excessive wear, or corrosion Pinned connectors for abrasion, deformation, and method of connection to the truss Fastening hardware for proper grade, deformation or excessive wear Welds for cracks and abrasion.

Visit or Call XSF for more information about Truss Inspection or how to preserve and prevent truss damage.

LARGEST ONLINE COLLECTION OF VIDEOS DEDICATED TO TRUSS

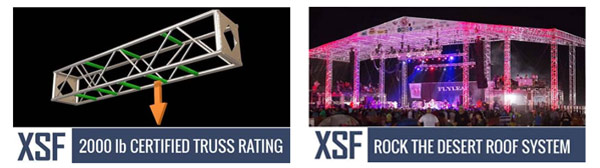

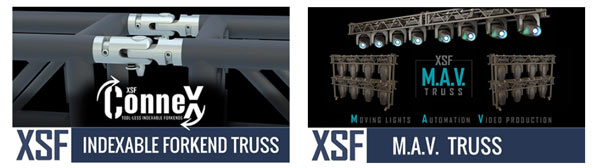

The Truss Industry is a broad scope category that has many topics. Over our long history we have consistently put together videos that we hope our customers find both entertaining, and informative. Currently, XSF offers a collection of over 30 videos! Some videos focus on our product development, with the aim of illustrating customer benefits ( ConneX, Protective Bolt Plate Truss or MAV) while some others are more focused on the education of Truss to help you make the correct choices when investing in Truss. (What is Lighting Truss, Load Tables, Allowable Load Ratings for Truss, or Aluminum Truss Inspection)